Understanding Weld Neck Flanges

Weld neck flanges, characterized by their extended neck design, are pivotal in ensuring robustness and reliability in pipeline connections. This article delves into the distinctive features, versatile applications, advanced welding techniques, and future advancements of weld neck flanges.

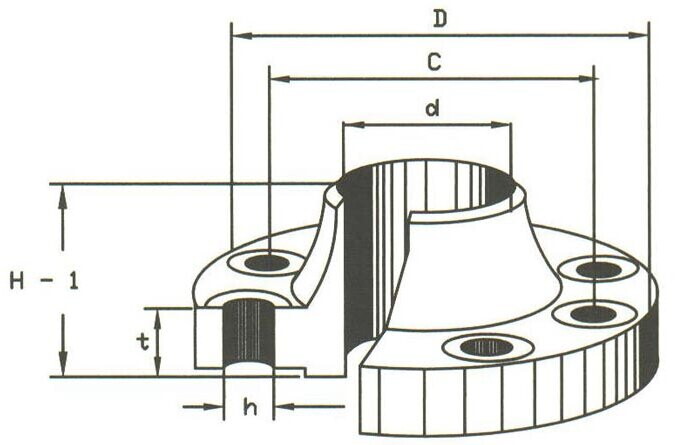

1. Distinctive Features

Weld neck flanges are available in various designs tailored to different sealing surface requirements, including flat-faced, raised-face, concave-convex, and groove-faced variations. Despite requiring more welding effort and additional welding rods compared to conventional flanges, their ease of installation and resilience to extreme conditions make them indispensable in critical sectors such as urban infrastructure, boiler pressure vessels, petroleum, chemical, shipbuilding, and pharmaceuticals.

2. Versatile Applications

With a nominal pressure range spanning from PN1.0MPa to PN25.0MPa, weld neck flanges excel in diverse and demanding environments due to their superior rigidity and sealing properties. They prove particularly effective in scenarios involving pipe thermal expansion, high temperatures, high pressures, or significant temperature fluctuations. Consequently, they find prominent usage in critical infrastructure setups like urban water supply and power systems, industrial facilities with boiler pressure vessels, and sectors dealing with petroleum, chemical processing, shipbuilding, and pharmaceuticals.

3. Advanced Welding Methods

Welding techniques for weld neck flanges encompass manual gas shielded welding, automatic swing gas shielded welding, and the cutting-edge internal and external submerged arc welding methods. Specialized manufacturers of high-pressure steel pipe towers have developed dedicated internal and external submerged arc welding machines, enhancing welding efficiency through double-sided penetration welding while ensuring uncompromised welding quality.

4. Precision Welding Process

The welding process for weld neck flanges involves pivotal steps such as precise positioning welding, meticulous preheating, stringent interpass temperature control, and adherence to specific welding environment requirements. Skilled and certified welders are essential for executing the process, ensuring precise preheating and interpass temperature control to guarantee welding quality. Moreover, maintaining an optimal welding environment, including controlling wind speed and humidity levels, significantly influences the welding outcomes.

5. Future Perspectives and Advancements

The ongoing maturation of production technology for weld neck flanges and the continuous evolution of welding processes signify a promising future. While the current quality of weld neck flanges is commendable, there is room for further process consolidation to elevate production efficiency and ensure sustained quality standards.

In conclusion, weld neck flanges, with their unique design attributes and exceptional performance capabilities, serve as indispensable components in pipeline connections across various industries. With the trajectory of welding technology advancement, the outlook for the continued application and refinement of weld neck flanges remains bright.

Related News

- Failure and Crack Analysis of an EO/EG Unit Tower Inlet Flange

- Pipe Flange Bolt Tightening in LNG Projects: Key Considerations

- Ultrasonic Testing of High-Neck Flange Welds

- Underwater Flange Connection Methods for Submarine Pipelines

- Key Technologies for Pressure Vessel Testing and Flange Connection Design

- Installation of Main Bolts for Lap Joint Flange in High-Temperature Gas-Cooled Reactors

- Structural Design and Finite Element Analysis of Anchor Flanges

- Key Welding Technology for High-Neck Flange and Steel Pipe Joints

- The Design and Calculation of Stamped Lap Joint Flanges

- Development of Manufacturing Large Anchor Flanges