Services

Technical Articles

Five Types of Flange Facings and Their Characteristics

- Posted: 06/16/2017 11:06:09

- Hits: 295

Flat Face The flat face flange facing is mainly used for wide flanges and piping systems with low pressures. The flat face flange facing and the contact surface of the corresponding gasket are distributed on both the inner side and outer side of the...

An Introduction to the Welding Neck Flange

- Posted: 06/03/2017 10:06:07

- Hits: 63

What is the welding neck flange? Welding neck flanges include long welding neck flanges, and raised face welding neck flanges, which are mainly used for the flange and pipe counterpart welding. Welding neck flanges have reasonable structures, good strength and high rigidity. They...

The Causes of Blowholes on Flange Castings and the Process Improvement Measures

- Posted: 05/15/2017 09:05:05

- Hits: 180

The flange castings are thin-walled gray iron castings. The production process includes resin sand modeling without using metal flasks, making sand core by cold core box, making coated sand core by hot core box, leaching and painting the whole sand model with...

The Manufacturing Process of Flange

- Posted: 05/12/2017 09:05:55

- Hits: 5222

The manufacturing process of flange mainly is divided into forging, casting, cutting and rolling. The casting and forging flanges have advantages that the blanks of them have accurate shape, size and low costs and only need simple process. But forging flanges have manufacturing...

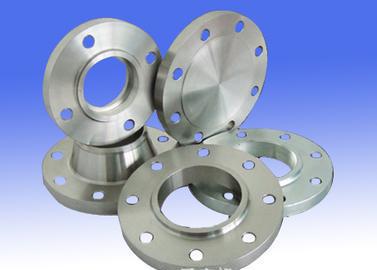

Stainless Steel Flange

- Posted: 04/26/2017 01:04:18

- Hits: 228

Flange is a kind of disc-shaped part, which is the most common in the pipe work. Flanges are in pairs and can match with the flanges on the valves. The flange is mainly used for pipe connection in the pipe work. We need to install a flange on each pipe that needs to be connected; we can use flanges...

Integral Flange

- Posted: 03/31/2017 09:03:09

- Hits: 361

Integral flange belongs to chemical Industry flange standard system, also known as HG flange. Integral flange is also called long neck flange. Its materials include carbon steel, stainless steel, alloy steel, etc. In the various domestic standards, we often use IF to express integral flange. Integral...

The Applications of Stainless Steel Welded Flanges

- Posted: 03/20/2017 04:03:57

- Hits: 49

Stainless steel welded flange is a kind of pipe fitting that is widely uesd, referring to those flanges with necks, which is transmitted by circular tube and connected with tubes by butt welding. Applications Stainless steel welded flange is not easy to deformation, has good sealing performance...

The Class And Technical Requirements of Welding Neck Flanges

- Posted: 02/24/2017 05:02:37

- Hits: 57

Welding neck flange is easy to use and can bear relatively large pressure. The materials for welding neck flange vary from low pressure asbestos pad, high pressure asbestos pad to metal pad due to the different pressure. We use different ways and processes in the development and manufacturing. For example,...

Flange Standard and Selection Method

- Posted: 02/24/2017 05:02:38

- Hits: 74

There are two types of flanges for petroleum and chemical, one is pressure vessel flange, another one is pipe flange. Both welded and welding neck flanges can be made with or without bush rings. When the equipment is made of stainless steel, we use carbon steel flange 7 and stainless steel...

Two Ways to Solve the Processing Problems of Stainless Steel Flanges

- Posted: 02/20/2017 05:02:48

- Hits: 64

There are some things we should pay attention to when it comes to the manufacturing of stainless steel flanges 1. Welding defect: stainless steel flange has a serious welding defect, if we use manual-mechanical way to make it up, there will be left with some trail and cause unevenness of the surface,...

Different Connection types of flanges

- Posted: 02/16/2017 11:02:22

- Hits: 56

The flange joint is to connect two pipes, fittings or equipment. Each of them is fixed to a flange plate. Then put flange gasket between two flange plates and use bolts to fasten them. Some fittings and equipment have flange plates, which is also belongs to flange joint. Flange joint is an important...

The Heat Properties Of Carbon Steel Flanges

- Posted: 01/11/2017 05:01:59

- Hits: 36

The Heat Properties Of Carbon Steel Flanges Anti-scouring The carbon steel flange' unique anti-scouring property has improved the actual wall thickness, its ring bending stiffness is 1.3 times than the actual wall. Long service life The tube's service life can reach over 50...