Services

Technical Articles

Simulation Tests of Failures Caused by Pickling Corrosion of SS Flanges

- Posted: 04/22/2022 09:04:43

- Hits: 19

1. Welding simulation tests Austenitic stainless steel has excellent corrosion resistance, but carbide aggregates at the grain boundary at the welding seam part, especially the heat-affected zone in actual production. Finally, intergranular corrosion occurs due to the corrosive medium. Therefore, to...

Electric Arc Materials Adding for Nuclear Grade Flanges (Part Two)

- Posted: 02/10/2022 08:02:12

- Hits: 23

(2) Microstructure After the arc additive TIG surfacing of the flange simulation part is completed, the metallographic samples are ground from the fusion line and the center of the surfacing layer respectively, and they are etched with ferric chloride plus hydrochloric acid solution. Observe...

Electric Arc Materials Adding for Nuclear Grade Flanges (Part One)

- Posted: 01/27/2022 08:01:51

- Hits: 34

Abstract: According to the corrosion status of the flange surface of a certain pipe end of a nuclear power plant and the site construction conditions, the method of arc materials adding of the flange surface was studied. Through the demonstration and analysis of the arc surfacing test of the...

The Calculation of the Flange Under the Internal Pressure and External Load

- Posted: 11/13/2021 08:11:32

- Hits: 2425

Abstract: In the design and manufacture process of the pressure vessel, the selection and design calculation of flanges have always been an unavoidable important content. Flanges for pressure vessels (forced sealing flanges) are often subjected to not only internal pressure but also axial...

Why Is It Not Recommended to Use SS304 for Sealing Bolts of Flange Connections?

- Posted: 10/16/2021 11:10:30

- Hits: 664

When the carbon steel or stainless steel flange is equipped with SS 304 bolts in the flange's sealing, leakages often occur in the operating state. (1) What are the differences between 304, 304L, 316 and 316L? 304, 304L, 316 and 316L are commonly used stainless steels in flange connections, including...

Anti-corrosion Technology of Oil and Gas Pipeline's Flanges and Bolts (Part Three)

- Posted: 09/12/2021 09:09:40

- Hits: 32

1.6 Viscoelastic anti-corrosion systems The viscoelastic body is mainly an anti-corrosion product developed by the Dutch company STOPAQ. It is a polyolefin-based flexible heavy-duty anti-corrosion material with a single-molecule non-bonded structure. This single-molecule non-bonded structural feature...

Anti-corrosion technology of oil and gas pipeline's flanges and bolts (Part Two)

- Posted: 08/24/2021 10:08:27

- Hits: 39

1.2 Molybdenum disulfide or grease The anti-corrosion technology of applying molybdenum disulfide or grease (calcium based grease) is one of the common ones used in anti-corrosion for metal. Because of the adhesion and lubricity of Molybdenum disulfide or grease, it can effectively...

Anti-corrosion Technology of Oil and Gas Pipeline's Flanges and Bolts (Part One)

- Posted: 08/09/2021 10:08:39

- Hits: 153

Abstract In the operation of oil and gas pipelines, flanges and bolts are often damaged by metal corrosion, which seriously affects their overall safety. Six mainstream anti-corrosion systems and their basic construction methods at home and abroad are introduced and analyzed, and their advantages...

Reasons for Cracks of Flanges

- Posted: 07/26/2021 11:07:43

- Hits: 550

A flange is a commonly used component in the pipeline. When a flange is connected to the pipeline, the welding is often adopted. However, if welding is not done properly, it will cause cracks between the flange and stainless steel pipe. Then, why do cracks appear for a flange in the welding process?...

The Research Method of Tightness of Bolted Flanges

- Posted: 05/10/2021 10:05:55

- Hits: 25

Sealing and leakage of bolted flanges In the past, people thought of the bolted flange connection being completely sealed or no leakage at the joint as that the pre-tightening pressure force on the gasket in the pre-tightened state cannot be less than the pre-tightened seal specific pressure y of the...

An Introduction to Flanges' Connections

- Posted: 04/06/2021 02:04:59

- Hits: 358

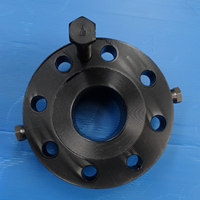

Flanges should not only meet the requirements for strength but also leakage rates when working. In addition, they should also have characteristics of convenient assembly and disassembly, low economic costs and good interchangeability. As shown in the Figure 1-1, the bolted flange...

A Brief Introduction to Butt Welding Flanges

- Posted: 03/08/2021 09:03:58

- Hits: 425

A butt welding flange is a kind of pipe fitting, which connects to the pipe. A butt welding flange is not easy to deform, has good sealing performance and wide applications. It is suitable for pipelines with large fluctuations in pressure or temperature as well as high-temperature, high-pressure...