Services

Technical Articles

Low-Temperature Flange Sealing Solutions for Cryogenic Chemical Pipelines

- Posted: 04/24/2025 01:04:39

- Hits: 1

Abstract On LNG carriers, boil-off gas (BOG) can be reliquefied into LNG using lower-temperature cooling media such as nitrogen and helium. However, achieving a reliable seal for cryogenic gases remains a significant technical challenge. Based on the LNG reliquefaction project, this paper analyzes...

Innovative Technology for Automatic Alignment in Underwater Flange Assembly

- Posted: 04/12/2025 10:04:05

- Hits: 1

Abstract: With the continued development of oil resources in deepwater areas, submarine pipeline transportation is widely recognized as the fastest, safest, most economical, and most reliable method. As the number of submarine pipelines increases, connecting pipelines on the seabed has become inevitable. However,...

Stamped Steel Slip-On Flanges

- Posted: 02/20/2025 06:02:43

- Hits: 14

Abstract The steel stamped slip-on flange is a new, non-standard pipe flange. This paper introduces the slip-on flange and details its structure and characteristics. A model is created using SolidWorks 3D modeling software and imported into ANSYS Workbench for finite element analysis. The slip-on flange...

Design and Finite Element Analysis of Anchor Flanges for Oil & Gas Pipelines

- Posted: 02/07/2025 02:02:21

- Hits: 14

Abstract Anchor flanges are critical components in oil and gas pipeline engineering, requiring precise design and calculation to account for complex engineering factors. Traditional design methods often rely on conventional calculation approaches, resulting in suboptimal structural dimensions, excessive...

Forming and Manufacturing Technology of Anchor Flanges

- Posted: 09/24/2024 02:09:12

- Hits: 39

An anchor flange is a key component in large-diameter, high-pressure, long-distance gas (oil) pipeline systems. This paper presents independent research and development work on the production technology of large anchor flanges. The structural parameter design was conducted by combining theoretical...

Structure and Materials of Anchor Flanges

- Posted: 09/07/2024 02:09:45

- Hits: 30

Anchor flanges are key components in long-distance gas (oil) pipeline transmission projects. They are welded onto the main gas (oil) pipelines and secured with cement piers. They are either half-buried or fully buried underground to prevent excessive pipeline displacement caused by combined forces such...

Flanges for Pressure Vessels

- Posted: 07/14/2024 04:07:43

- Hits: 197

Flanges are essential components in the design and construction of pressure vessels. They connect pipes, valves, and other equipment to the vessel, ensuring a secure and leak-proof seal. Flanges play a crucial role in maintaining the structural integrity and safety of pressure vessels. Types...

An Introduction to Socket Welded Neck Flanges

- Posted: 07/03/2024 03:07:23

- Hits: 18

A welded neck flange is a type of flange used in piping systems to provide a secure, reliable connection between pipes, valves, pumps, and other equipment. It is designed with a long, tapered hub that is welded to the pipe. This design provides reinforcement in the flange area, reducing stress and ensuring...

Heat Treatment & Mechanical Properties of ASTM A350 LF3 Flanges (Part Two)

- Posted: 05/28/2024 08:05:48

- Hits: 101

3. Process tests The flange forging deformation must be sufficient; the total forging ratio should be greater than and equal to 6.0, and the final forging temperature should not be lower than 850℃. Rough machining should be performed after forging. According to literature reports, ASTM A350 LF3 steel...

Heat Treatment & Mechanical Properties of ASTM A350 LF3 Flanges (Part One)

- Posted: 05/07/2024 07:05:41

- Hits: 161

Abstract ASTM A350 LF3 steel blind flanges and butt-welded flanges of different sizes need to be tempered to meet the requirement for mechanical property. In addition to the chemical composition of the steel, to determine the appropriate tempering process, ASTM A350 LF3 steel test block...

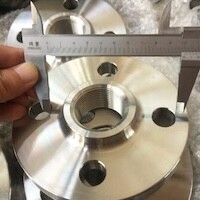

High-pressure Wellhead Device Valve Body End Threaded Flanges

- Posted: 02/20/2024 01:02:49

- Hits: 17

In the high-pressure oil and gas wellhead devices produced by some manufacturers in China, the end face of the valve body adopts a structural design with a threaded flange and an octagonal steel gasket seal. Since the connecting flange is not in contact with the medium, the valve body is easy to forge...

Threaded Flanges at the End of Valve Bodies of High-pressure Oil & Gas Wellhead Devices

- Posted: 11/15/2023 01:11:00

- Hits: 50

Abstract: The structure of the threaded flange at the end of the valve body of the high-pressure oil and gas wellhead device is introduced. The strength calculation method of this type of threaded flange and its common specifications and dimensions are given. The threaded flange is safe and reliable...