News

News

Five technical requirements in flange forging process (part three)

- Posted: 02/11/2019 04:02:37

- Hits: 23

2. Technical requirements for shape, size and surface condition of flange forgings Based on reliable raw material quality, one of the tasks of flange forging processing is to obtain the required shape, size and surface condition to meet the requirements of parts design, processing and use conditions....

Five technical requirements in flange forging process (part two)

- Posted: 01/31/2019 03:01:16

- Hits: 36

Mechanical property The mechanical properties of raw materials include properties at room temperature and high temperature, such as strength index, plasticity index, impact toughness, hardness, fracture toughness, permanent strength, fatigue properties, stress corrosion resistance, etc., which should...

Five technical requirements in flange forging process (part one)

- Posted: 01/17/2019 05:01:33

- Hits: 72

The use conditions of flanges refer to the importance, working conditions, assembly and disassembly difficulty, complexity of them, as well as force, working temperature, corrosion degree, and other factors. From the basic principle that the forging is to serve and meet the use conditions of the...

Quality Control and Repair in Flange Forging Production

- Posted: 01/07/2019 06:01:36

- Hits: 106

In order to ensure that the flange forgings have the dimensional accuracy and mechanical properties required by the design, the quality of the forgings must be controlled, that is, the entire production process from selecting raw materials to post-forging heat treatment must be controlled to ensure...

How to improve the plasticity of metal in forging process

- Posted: 12/28/2018 05:12:23

- Hits: 221

Most of the time, plastic processing of metal forgings is a series of processes that a simple-shape blank turns into the final product with required shape and size via plastic deformation. Good metal plasticity facilitates plastic forming, and from the angle of plastic processing, the main ways to improve...

Oxidation and decarburization of forgings during heating process

- Posted: 12/19/2018 03:12:28

- Hits: 952

Oxidation is a phenomenon in which a flange forging blank (metal raw material) chemically reacts with an oxidizing gas in the heating process, forming an oxide skin on the metal surface of the forging. For example, when steel is heated to a high temperature, ferrum on the surface layer reacts with oxygen,...

Sealing principle of pressure vessel flange

- Posted: 12/11/2018 05:12:13

- Hits: 241

Pressure vessel flanges are common and basic components that connect various parts of pressure vessel. They are widely used in petrochemical, electric power, atomic power, and other industries. For vessels, the function of flanges, gaskets, connecting bolts, studs, screws is to combine different pressure...

How does internal cracks of forging blank occur during heating

- Posted: 12/10/2018 04:12:13

- Hits: 188

Internal Crack of Flange Blank When the blank is heated, if its internal stress exceeds its strength limit at a certain temperature, the cracks will be generated. Usually, there are temperature stress, structural stress, and residual stress. Temperature Stress The temperature difference is generated...

An incident of toxic chemical spill due to flange gaskets breakage

- Posted: 11/12/2018 02:11:29

- Hits: 98

On November 4th, People in Quangang (a district in Quanzhou, Fujian Province) were jarred by an odor permeating in the air that spread from the area of Shangxi Village, Houlong Town and Fengqian Village, Fengwei Town. At the same time, parts of the sea were contaminated by a tawny oil-like leakage....

12 kinds of flanges (part two)

- Posted: 11/01/2018 05:11:09

- Hits: 37

Blind Flange It is a flange without any bore in the middle in order to block off media through a pipeline, like what welded cap and casing cap function, except that only casing cap and blind flange are able to be uninstalled at any time. Blind Flange with Anti-Corrosion Lining It is a kind of blind...

12 kinds of flanges (part one)

- Posted: 10/27/2018 03:10:42

- Hits: 67

As a kind of indispensable spare part in piping design, flanges can be used in a wide range of fields, such as industrial furnace, water supply and drainage, heating and ventilation. Materials: Forged steel, WCB carbon steel, stainless steel, 316L, 316, 304L, 304, 321, Cr-Mo steel, Cr-Mo-V steel, 316Ti,...

The Shanghai Pressure Vessel Exhibition 2018

- Posted: 07/21/2018 01:07:39

- Hits: 135

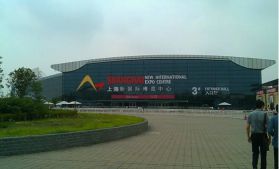

Exhibition Name: The Shanghai Pressure Vessel Exhibition 2018 Exhibition Date: From 2018-8-23 to 2018-8-25 Exhibition Venue: Shanghai Address: Shanghai New International Expo Center Organizer: China Chemical Enterprise Management Association & China Chemical Industrial Mechanism Power Technology...