News

News

The Difference between Flanges and Blind Flanges

- Posted: 02/01/2021 02:02:26

- Hits: 552

The blind flange has no holes in the middle. It is mainly used for sealing the pipe opening. Its function is the same as that of the pipe plug and the pipe cap. The difference is that the blind flange is a detachable sealing device while the pipe cap cannot...

Problems in Welding Process of the Flange and Flange Blank

- Posted: 01/06/2021 04:01:53

- Hits: 54

With the continuous development of the stamp flange blank, the flange processing technology has also developed rapidly. However, the flange has many physical and chemical properties, such as a strong oxidizing nature, a low melting point, fast heat conduction, a large coefficient of linear expansion, large...

The Pros and Cons of Flanges

- Posted: 12/28/2020 10:12:47

- Hits: 1456

1. Slip on plate flange Advantages: Convenient supply of raw materials, a simple manufacturing process, low costs and a wide range of applications. Disadvantages: The slip on plate flange has poor rigidity, so it should not be used in chemical process piping...

How to Choose the Welding Method of Pipe Flanges

- Posted: 12/14/2020 03:12:53

- Hits: 136

Pipe flange welding includes flat welding, butt welding, and socket welding. 1. Choose the appropriate flange material according to the material of the pipe. For example, stainless steel pipes are definitely not allowed to use carbon steel flanges. 2. Pick the proper flange...

The Comprehensive Knowledge of Flanges

- Posted: 11/24/2020 02:11:55

- Hits: 35

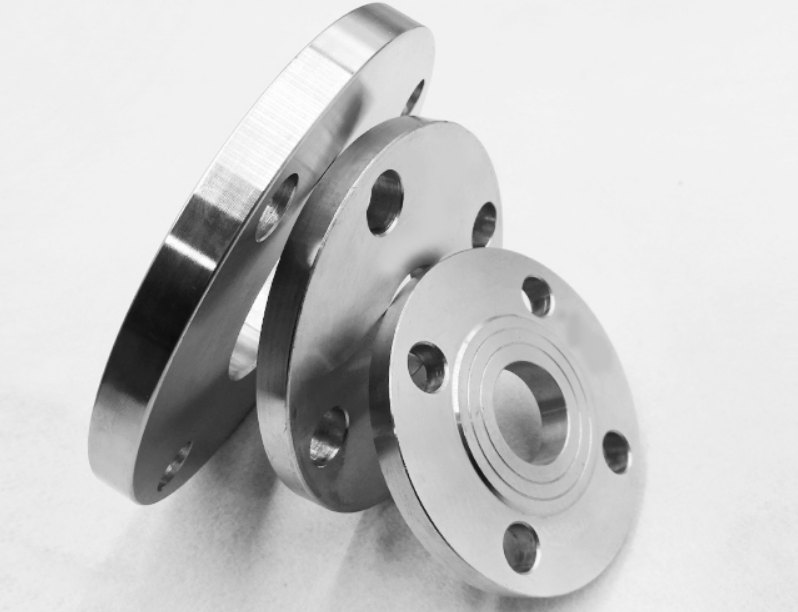

This article talks about the comprehensive knowledge of flanges. Flange is an important part of connecting pipe and pipe. It is connected to the pipe end. There are holes on the flange. The two flanges are connected tightly with wear-resistant bolts, and the flange is sealed with gasket. There are two...

Production Process of Forged Flange And Cast Flange

- Posted: 11/05/2020 02:11:37

- Hits: 32

This news is going to talk about the production process of forged flange and cast flange. Flange is a kind of connection sealing parts. If there are quality problems in the production process, there will be leakage, resulting in economic losses, environmental damage and even safety accidents. So the...

What Is Flange And What Are The Types of Flange?

- Posted: 10/23/2020 02:10:11

- Hits: 288

In fact, the name of flange is a transliteration. It was first put forward by an Englishman named Elchert in 1809. At the same time, he proposed the casting method of flange. However, it was not widely used in a considerable period of time later. Until the early 20th century, flange was widely...

Pros and Cons of Forged Flanges and Cast Flanges

- Posted: 10/11/2020 03:10:23

- Hits: 126

The forged flange and the cast flange are two common flange types in the market. Cast flanges have low cost, low technical requirements, a short mass production cycle. Forged flanges have a slightly higher price and good quality. Let's focus on analyzing the pros...

Operational Norms of Forged Flanges

- Posted: 09/28/2020 05:09:10

- Hits: 18

In the production of forged flanges, it is often necessary to heat the flange blank at high temperature and then forge it by a hammer. Through constant blows, the density of the flange blank is continuously increased. And then the flange is produced by shaping and drilling. There are certain risks...

Knowledge of a Lap Joint Flange

- Posted: 09/09/2020 04:09:52

- Hits: 32

What is a Lap Joint Flange/Loose Flange? A lap joint flange is used to cover the end of a pipe with flanging, the steel ring and other processes. The steel ring or flanging is a sealing surface, and the function of a flange is to press them tightly. It can be seen that the lap joint...

What Are Three Methods for Local Repair of Flanges

- Posted: 08/29/2020 05:08:31

- Hits: 116

The application of flange plays an important role in many aspects, including petrochemical industry, energy industry, scientific research and military industry. However, in the reactor of refinery, the production environment of flange is very bad, and the performance of flange must be excellent, because...

How to Identify the Authenticity of Stainless Steel Flange

- Posted: 08/15/2020 04:08:07

- Hits: 25

Nitric acid spot test: A notable feature of stainless steel flanges is inherent corrosion resistance to concentrated nitric acid and dilute nitric acid. This property makes it easy to distinguish from most other metals or alloys. 1. Copper sulfate spot test: Copper sulfate point test is the simplest...