News

News

Cracks & Corrosion in the Heat-affected Zone of DSS Flange (Part One)

- Posted: 09/10/2022 05:09:21

- Hits: 14

Abstract: Aiming at the leakage during the testing of the seawater pipeline system of a nuclear power plant, from the construction to the testing process, the multi elimination methods were used to analyze the corrosion. By analyzing the properties of the material, distribution of stress, and the medium...

Analysis Results of 304 Stainless-steel Flanges in Propylene

- Posted: 08/22/2022 03:08:47

- Hits: 24

Discussion of results 0Cr18Ni9 stainless steel has good corrosion resistance, especially excellent resistance to intergranular corrosion, so it is an ideal material for chemical equipment such as acid-resistant containers, pipes and heat exchangers. The material of the failed flange was severely sensitized,...

Failure Analyses of 304 Stainless-steel Flanges in Propylene

- Posted: 08/12/2022 11:08:34

- Hits: 39

The stainless-steel flange in the pressure pipeline of a polypropylene plant of a petrochemical plant leaked during the operation of several flange necks. After repair welding, there was no leakage at the welded part in a short time, but other flanges still leak. The outer wall of the flange is painted,...

Characteristics & Protective Measures of Crevice Corrosion of SS Flanges

- Posted: 07/27/2022 09:07:26

- Hits: 20

1. Characteristics of crevice corrosion of stainless steel flanges are as follows: (1) The corrosion of the metal in the crevice is caused by the existence of foreign matter or structural reasons on the metal surface, which makes the migration of corrosion related substances in the solution in the crevice...

The Analysis of Causes of Corrosion of SS 304L Flanges

- Posted: 07/13/2022 08:07:22

- Hits: 55

A printing and dyeing equipment factory added water for the pressure test to the pipeline connected to stainless steel 304L raised face flanges. The pressure test water was not emptied in time in the pipeline. After about 15 days, it was found that the flange's sealing surface was corroded. The...

Causes of Corrosion of SS Flanges in a Nuclear Power Plant (Part Two)

- Posted: 05/23/2022 09:05:46

- Hits: 61

2. The analysis of the causes of corrosion of stainless steel flanges 2.1 The analysis of the material The grade used for SEC stainless steel flange is 316L, and its PRE (pitting corrosion resistance equivalent) calculated by the formula is lower than that of duplex stainless steel. This kind of stainless...

Causes of Corrosion of SS Flanges in a Nuclear Power Plant (Part One)

- Posted: 05/09/2022 08:05:42

- Hits: 30

Overview The important water system (SEC) is an open circulation system; its internal medium is seawater, and its main function is to cool the cooling system of the cooling equipment. The main function of RRI is to cool various types of heat exchangers in the nuclear island. The heat load of the nuclear...

Physical & Chemical Inspection of Pickling Corrosion of SS304L Flanges

- Posted: 04/16/2022 09:04:45

- Hits: 46

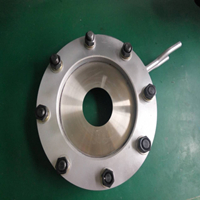

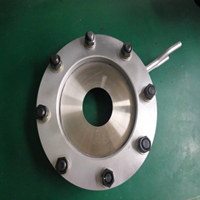

The stainless steel flange and stainless steel pipe produced by a company need to be pickled after welding. After pickling, it was found that thinning occurred due to corrosion for one of the flanges in the welding seam and its surrounding areas. The flange is made of stainless steel 304L....

Steel Flanges

- Posted: 03/31/2022 09:03:20

- Hits: 11

Overview There are many types of flanges, and there are many working conditions. How to choose the right flange in the actual situation? The specific selection types and occasions will be talked about in this article. Types of flanges Flanges can be classified into weld neck flanges,...

Failures Caused by Manufacturing & Installation of SS Flanges (Part Two)

- Posted: 03/09/2022 09:03:33

- Hits: 28

3. Welding processes and failure factor analysis of flanges In order to improve the reliability of the connection between the flange and pipeline, welding is generally used. Under the action of a high-temperature heat source during fusion welding, the area where the structure and properties...

Failures Caused by Manufacturing & Installation of SS Flanges (Part One)

- Posted: 02/10/2022 07:02:26

- Hits: 142

Abstract: Two typical cases in chemical plants are listed. The failures of flanges are caused by manufacturing and installation. After analyzing and studying the failed parts, it is found that the surface defects in the forging process and the improper selection of welding materials or processes are...

Current Status of Research on Bolted Flanges

- Posted: 01/06/2022 02:01:36

- Hits: 19

In recent decades, the work done by domestic and foreign researchers on bolted flanges has focused on the performance of gaskets and loosening of bolts, and significant progress has also been made in some areas. Bolted flanges are generally in the assembly structure, and accurate and...