News

News

Treatment of Leakages of Oxygen Pipeline Check Valve Flanges

- Posted: 08/23/2023 02:08:00

- Hits: 137

Formulating a treatment plan Oxygen pipeline maintenance hot work is the hot work with the highest risk in Steel. Oxygen has good combustion-supporting properties. There should be careful consideration about formulating plans when hot work occurs. Any carelessness may cause major accidents. The company...

Leakages in Check Valve Flanges of Oxygen Pipelines

- Posted: 08/07/2023 08:08:24

- Hits: 10

The emergency failure of the stainless steel check valve flange of the oxygen pipeline of two sets of air separation plants is briefly described, and emergency measures are taken from the perspective of production and safety, and a detailed emergency repair plan is formulated. Through the stages of...

The Leakage between Valve Bodies and Socket Welded Flanges

- Posted: 07/31/2023 08:07:37

- Hits: 67

Abstract: the microscopic morphology of the cracked fracture, corrosion products and metallographic structure of the joint between the valve body and the socket welded flange were introduced in this article. The causes of failures, such as the incomplete penetration of the welding seam between the valve...

Analyzing Stainless Steel Flanges in LNG Gasification Stations (Part two)

- Posted: 04/07/2023 03:04:39

- Hits: 12

1.3 Analyzing the impact on marine and atmospheric environment The LNG gasification station is located near the coast, which is 1 km away from the coast and belongs to the marine atmospheric environment. The station is located in a low-lying area surrounded by mountains, and the air humidity is relatively...

Analyzing Stainless Steel Flanges in LNG Gasification Stations (Part one)

- Posted: 03/29/2023 02:03:59

- Hits: 20

1.1 Analysis of failure mechanism of corrosion Austenitic stainless steel 304 has excellent corrosion resistance and weldability. Studies have shown that the main forms of corrosion of austenitic stainless steel 304 welding seam are intergranular corrosion and stress corrosion. 1. 1. 1 Intergranular...

Inspection of Stainless Steel Flanges of LNG Gasification Stations

- Posted: 03/15/2023 10:03:49

- Hits: 41

Abstract: After an LNG gasification station was put into operation for 10 years, leakage due to corrosion was found in the heat-affected zone of the stainless steel flange at the liquid phase inlet of the air-temperature gasifier and the gas phase outlet of the storage tank from the supercharger. Chemical...

Causes of Cracks in 304 Stainless Steel Pipe Fittings

- Posted: 02/08/2023 07:02:05

- Hits: 417

Stainless steel 304 has good heat resistance, corrosion resistance, cold and hot processing and welding, and is widely used in high-temperature corrosion parts of oil refining and chemical equipment, which is very important to ensure the safe operation of the equipment. During the inspection of a new...

Failures of Welding Seams of Slip-on Flanges of Thermal Pipelines

- Posted: 01/28/2023 12:01:58

- Hits: 62

When the heating medium is hot water, the working pressure is up to 2.5MPa due to the low pressure of the thermal pipeline. When the heating medium is steam, the working pressure is up to 1.6MPa. Therefore, in the construction process, the pipeline and its components adopting low carbon steel can meet...

Application of TIG Welding to SS Slip-on Flanges (Part two)

- Posted: 12/25/2022 10:12:13

- Hits: 54

4. Welding steps (1) Requirements for base materials: stainless steel 304, 304L, 316, and 316L are used for slip-on flanges and pipe fittings, and it is better to use the same type of stainless steel for flanges and pipes. The diameter d of the inner hole of the slip-on flange is slightly larger than...

Application of TIG Welding to SS Slip-on Flanges (Part one)

- Posted: 12/11/2022 10:12:47

- Hits: 47

Abstract: Stainless steel slip-on flange and pipe fittings are connected by TIG welding, and self-flux welding is adopted for the flange’s sealing surface. The non-sealing surface of the flange is welded with wire to realize the function of the connection of the flange. 1. Introduction...

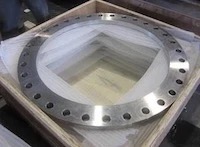

Control Deformation Caused by Welding of Slip-on Flanges with Large Diameters

- Posted: 10/22/2022 10:10:02

- Hits: 207

Abstract: In the manufacturing process of pressure vessels, deformation caused by the welding of slip-on flanges with large diameters often occurs. By analyzing the causes of deformation, the measures to control the deformation are proposed to provide guidance for preventing deformation caused by welding...

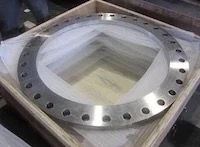

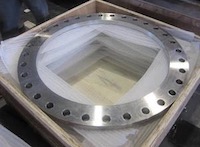

Research on the Manufacturing Process of Large Flanges

- Posted: 09/24/2022 10:09:46

- Hits: 36

With the advancement of science and technology, modern petrochemical enterprises are developing in the direction of large scale and complication. The large-scale equipment has brought opportunities to the manufacturer, but it has also brought greater challenges. In the manufacturing process of large...