News

News

Exploring Blind Flanges: Design and Practical Applications

- Posted: 02/28/2024 03:02:51

- Hits: 109

Blind flanges hold a pivotal role in industrial pipelines, ensuring secure sealing and facilitating essential maintenance procedures. From containing pressure within vessels to allowing for efficient flow control, these components are integral to the smooth operation of various industrial processes....

Understanding Weld Neck Flanges

- Posted: 02/24/2024 03:02:29

- Hits: 59

Weld neck flanges, characterized by their extended neck design, are pivotal in ensuring robustness and reliability in pipeline connections. This article delves into the distinctive features, versatile applications, advanced welding techniques, and future advancements of weld neck flanges. 1....

Stainless Steel Flange Installation and Maintenance Guide

- Posted: 02/21/2024 04:02:20

- Hits: 33

In pipeline connections, stainless steel flanges serve as vital components, particularly in environments demanding high corrosion resistance and substantial pressure handling. While inheriting traits like corrosion resistance and robust rigidity, stainless steel flanges necessitate proper maintenance...

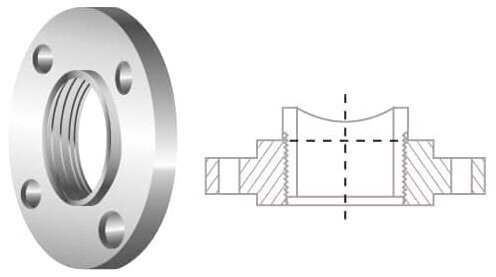

The Lap Joint Flange

- Posted: 02/05/2024 08:02:06

- Hits: 85

Lap joint flanges are a type of flange used in piping systems to connect two pipes or pipe fittings. They consist of a flat, circular plate with a raised inner lip that fits over the end of the pipe. The flange is then secured to the pipe by bolting it together with another lap joint flange. One of...

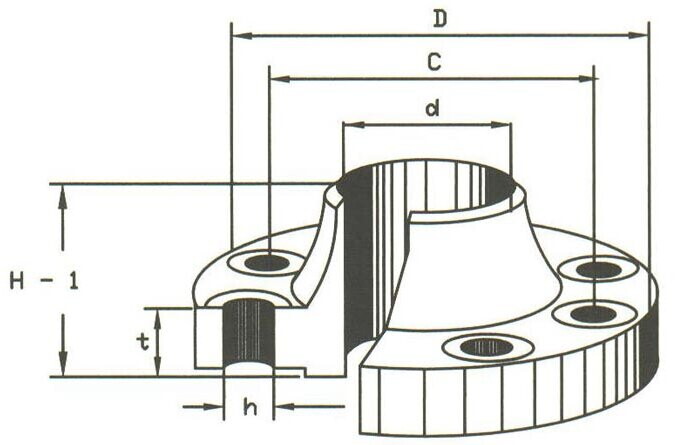

Socket Welded Neck Flanges

- Posted: 01/25/2024 01:01:53

- Hits: 33

The socket welded flange with necks is a type of flange commonly used in piping systems. It is designed to provide a strong and leak-proof connection between pipes or pipe fittings. This type of flange has a raised face with a smooth surface, which allows for easy welding and ensures a good seal. One...

Analysis of Pickling Corrosion of SS 304L Flanges (Part Two)

- Posted: 01/11/2024 11:01:27

- Hits: 20

2. Simulation tests of welding Austenitic stainless steel has excellent corrosion resistance, but austenitic stainless steel often forms grain boundary carbide accumulation at the welding seam in actual production, especially in the heat-affected zone after welding, and finally causes intergranular...

Analysis of Pickling Corrosion of SS 304L Flanges (Part One)

- Posted: 12/18/2023 08:12:03

- Hits: 66

Abstract: Corrosion occurred in the pickling process after welding the stainless steel 304L flange and stainless steel pipe. Macroscopic inspection, chemical composition analysis, metallographic inspection, SEM, heat treatment simulation and other methods were used to analyze the corrosion at...

Lap Joint Flanges

- Posted: 12/11/2023 09:12:12

- Hits: 178

A flange is one of the most important and common parts for connecting pipelines, valves, instruments, and equipment in production, storage, transportation, and pipeline transportation devices in the oil, gas, chemical, and other industries. A lap joint flange is a type of flange used in piping systems...

Leakages at the Welding Part between Valve Bodies and Socket Welded Flanges

- Posted: 11/22/2023 09:11:45

- Hits: 44

Abstract The micromorphology of the crack fracture surface and corrosion products and the metallographic structure of the welding seam at the connection between the valve body and the socket welded flange are introduced. The causes of failure such as incomplete welding between the valve body and the...

Stainless Steel Flanges

- Posted: 10/25/2023 02:10:31

- Hits: 24

In the realm of industrial applications, stainless steel flanges have stood the test of time as a reliable and versatile component. These essential fittings are used to connect pipes, valves, and other equipment in various systems, ensuring a secure and leak-free connection. The enduring popularity...

Why Do Stainless Steel Flanges Crack During Welding?

- Posted: 09/26/2023 10:09:45

- Hits: 243

A flange is a commonly used pipe component. When flanges and pipes are connected, welding is often used. However, if improper operation is performed during welding, cracks will occur between the flange and the stainless steel pipe. Why does the flange crack during welding? How to avoid flange cracking?...

Surface Treatment of Stainless Steel 304 Flanges

- Posted: 09/05/2023 05:09:18

- Hits: 24

Stainless steel 304 flanges are a vital component in various industrial applications. These flanges are made from an alloy that contains chromium and nickel, which gives them excellent corrosion resistance properties. They are widely used in industries such as oil and gas, chemical, petrochemical, and...