Latest Standard for Forging Blind Flanges and Applications

Major function of blind flanges is working as the connection between pipelines and the connection of blind flange is to link pipes, pipefitting and equipment, and fixed on the flange. Firstly, install the blind flange and then fixed flanged with bolts, this is the process of connecting flanges. Some kinds of flanges have own pipes and equipment and belong to the connection of blind flange at the same time.

Applications of blind flanges: closing the pipeline, the same function as the plugs, at the same time, has the dust-proof, waterproof and anti-corrosion effect.

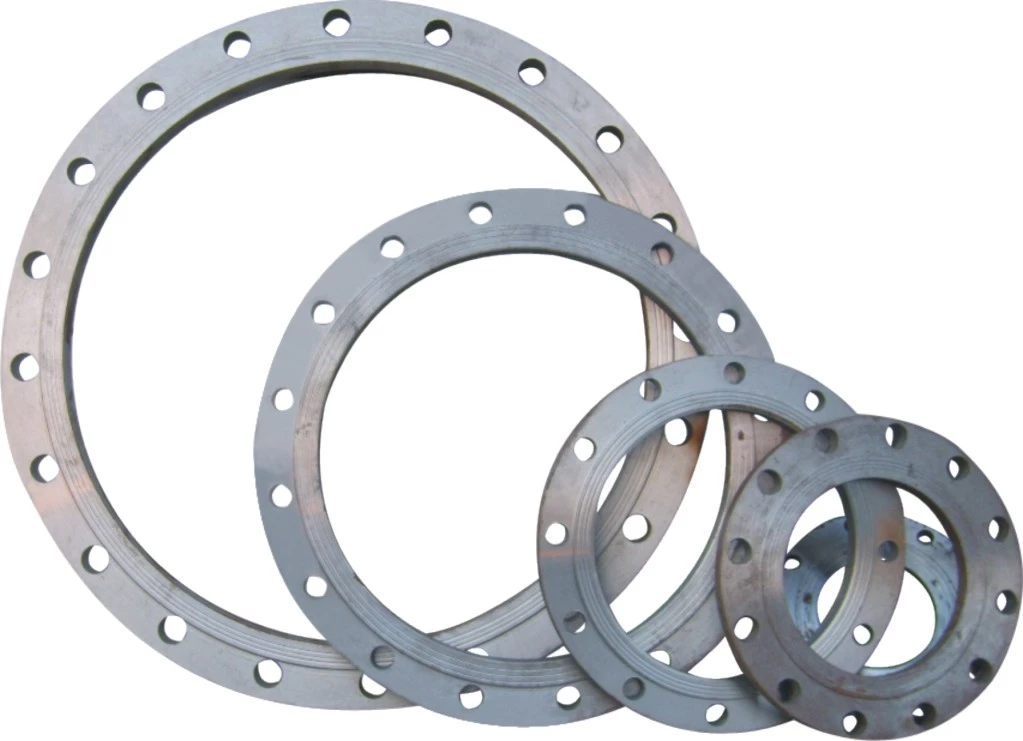

According to the manufacturing process, blind flanges can be divided into threaded flanges and welded flanges. Thread flanges can be used in pipelines with low pressure, while weld flanges should be used in high pressure or large diameter pipeline. When applied in pipelines, blind flanges with different pressure and diameters of screw threads will also cause discrepancy in diameters and number of screw threads.

It’s rare to see blind flanges in family pipelines, for household pipes generally has low pressure. On the other hand, blind flanges have a wide range of applications in industrial pipelines, especially in boiler rooms, for there is a place with numerous pipes and high pressure, so there is a large demand for blind flanges.

Blind flanges should be set in isolation parts, such as the connected joint and cutting mouth. It’s commonly recommended spectacle blank flanges, for one time-used parts can also use circular blind flanges.

Standards of flange: HG20601-1997 and HG20622-1997 in Ministry of Chemical Industry, ANSIB16.5 in American Standard and GB / T9123.1-2000-GB / T9123.4-2000 in Chinese Standard.

Types of flange sealing: flat face (FF), raised face (RF), male and female face (MFM), tongue and groove face (TG) and rising joint face (RJ).

Related News

- Low-Temperature Flange Sealing Solutions for Cryogenic Chemical Pipelines

- Innovative Technology for Automatic Alignment in Underwater Flange Assembly

- Stamped Steel Slip-On Flanges

- Design and Finite Element Analysis of Anchor Flanges for Oil & Gas Pipelines

- Forming and Manufacturing Technology of Anchor Flanges

- Structure and Materials of Anchor Flanges

- Flanges for Pressure Vessels

- An Introduction to Socket Welded Neck Flanges

- Heat Treatment & Mechanical Properties of ASTM A350 LF3 Flanges (Part Two)

- Heat Treatment & Mechanical Properties of ASTM A350 LF3 Flanges (Part One)