Key Welding Technology for High-Neck Flange and Steel Pipe Joints

The core technology in steel pipe tower fabrication is the welding of high-neck flanges to steel pipes. An enhanced welding technique has developed, building on the original process. This new method not only ensures a high first-time pass rate but also improves production efficiency, facilitating the large-scale production of steel pipe towers.

The Anhui Power Eastward Transmission Project is China’s first double-circuit, ultra-high-voltage AC transmission line employing a single-tower design. Spanning 656 kilometers, it begins in Huainan, Anhui, passes through southern Anhui and northern Zhejiang, and terminates at Shanghai. the company is responsible for fabricating six tower types and 23 steel pipe towers, with a total weight of 3,756 tons of steel pipe.

The total welding length for this project is substantial, with 19,688 meters of welding completed—significantly higher than the volume required for comparable angle steel towers.

The project includes 5,096 butt welds between high-neck flanges and steel pipes, totaling approximately 5,253 meters, representing 26.68% of the total weld length. All welds must meet first-class welding quality standards.

This is the first transmission line in China to use steel pipe towers along the entire route. It also marks the first large-scale implementation of high-neck flange and steel pipe butt welding processes. As a result, domestic manufacturers are producing this type of tower for the first time and do not have established welding expertise.

Before this project, the company specialized in producing over 100,000 tons of angle steel towers annually, with limited experience in steel pipe towers. Consequently, there was a lack of resources and technical personnel for assembly and welding.

The core technology in steel pipe tower fabrication is the welding of high-neck flanges to steel pipe butt joints. Achieving a high initial inspection pass rate, operational efficiency, and seamless execution is critical for large-scale steel pipe tower production.

To ensure the accuracy and effectiveness of the welding process, we conducted comprehensive process assessments covering all stages. After receiving the construction drawings, the company reviewed the existing welding process assessments and carried out additional evaluations to address any gaps, in accordance with JGJ81-2002 standards and the project design specifications. Based on welding trials, we developed three sets of welding processes and created 26 procedural documents to meet the project's requirements. The key welding methods we adopted are:

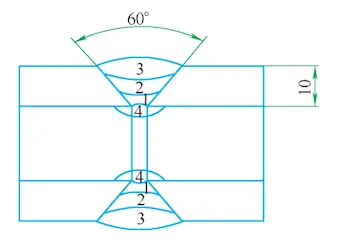

For steel pipes with a diameter ≥273 mm and high-neck flanges, the inner and outer ring welds are executed first, followed by root cleaning of the outer groove. The original V-shaped groove is reshaped into a U-shaped groove, after which gas-shielded welding is applied to fill and seal the groove.

For steel pipes with a diameter <273 mm and high-neck flanges, we adopted a single-sided gas-shielded welding process with double-sided forming. The steel pipe rotates at a uniform speed while the welder operates the welding torch at the 1 o'clock position. These processes passed welding tests and met production requirements, with a weld inspection pass rate exceeding 97%. However, they were not optimal for mass production and required specialized personnel for root cleaning.

At the mid-point of the project, we introduced two new welding methods to improve efficiency:

For steel pipes with diameters ≥273 mm, we used a combination of gas-shielded welding for the base, filling, and capping, followed by submerged arc welding at the 6:30 o'clock position in the inner groove. This method eliminated root defects, significantly improved the inspection pass rate, and reduced the need for root cleaning, thereby enhancing overall efficiency.

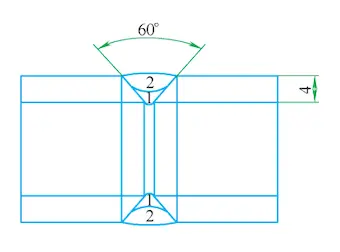

For steel pipes with diameters <273 mm, we introduced integrated pipeline forming equipment, using argon arc welding for the base and gas-shielded welding for the filling and capping. The high penetration of argon arc welding ensured complete melting at the groove root.

By implementing these welding methods, we achieved a circumferential weld inspection pass rate of over 99%, significantly improving production efficiency and enabling a monthly production capacity exceeding 2,000 tons.

Given the stringent quality requirements for butt welds between steel pipes and high-neck flanges, we developed detailed procedures for each step and implemented comprehensive quality control measures at every stage:

Steel Pipe Cutting: A V-shaped groove is cut with a 30° groove angle. If the pipe end is out of alignment, it is corrected using an angle grinder to achieve a 0-2mm blunt edge tolerance.

Assembly of High-Neck Flange and Steel Pipe: A minimum of three tack welds are applied, ensuring even spacing and compliance with specified length and penetration standards.

First-Level Weld Preparation: Prior to welding, any oil, rust, or other contaminants are removed, and the tack welds are shaped to a climbing pattern to ensure optimal weld integrity.

First-Level Weld Inspection: All first-level welds are subject to 100% inspection within 24 hours, with random checks on branch pipe welds. A third-party testing agency conducts a thorough inspection to ensure compliance with standards.

We ensured welder competency by providing comprehensive theoretical and practical training to 25 certified welders, significantly enhancing welding quality and performance.

Figure 1: welding sequence from 1 to 4

Figure 2: welding sequence from 1 to 2

|

Pass |

Welding Method |

Welding Rod or Welding Wire |

Flux or Shielding Gas |

Shielding Gas Flow (L/min) |

Welding Current (A) |

Arc Voltage (V) |

Welding Speed (em/min) |

Specification (mm) |

|

1 |

GMAW-Ar |

ER50-3 |

14% CO₂ + 86% Ar |

15-25 |

110-160 |

16-22 |

17-25 |

1.2 |

|

2 |

GMAW-Ar |

ER50-3 |

14% CO₂ + 86% Ar |

15-25 |

220-280 |

25-35 |

25-35 |

1.2 |

|

3 |

GMAW-Ar |

ER50-3 |

14% CO₂ + 86% Ar |

15-25 |

220-280 |

25-35 |

25-35 |

1.2 |

|

4 |

SAW-S |

H08A |

SJ101 |

- |

400-600 |

24-40 |

25-45 |

3.2 |

|

Path |

Welding Method |

Welding Rod or Wire |

Flux or Shielding Gas |

Shielding Gas Flow (L/min) |

Welding Current (A) |

Arc Voltage (V) |

Welding Speed (em/min) |

Specification (mm) |

|

1 |

GTAW |

ER50-3 |

100% Ar |

8-12 |

95-125 |

- |

25-40 |

1.2 |

|

2 |

GMAW-Ar |

ER50-3 |

14% CO₂ + 86% Ar |

15-20 |

100-130 |

15~25 |

20-30 |

1.2 |

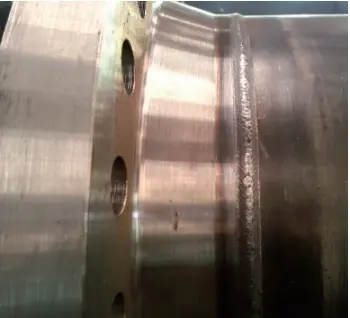

Figure 3: Main Pipe First-Level Weld

Figure 4: Branch Pipe First-Level Weld

Two key welding technologies were employed in this project to enhance production efficiency and ensure high-quality results:

Submerged Arc Welding: This widely used technique is primarily employed to mitigate root defects in the welds.

Pipeline Integrated Forming Machine: This equipment streamlines the welding process, enhancing both reliability and production efficiency through integrated automation.

In the fabrication of steel pipe towers for the Anhui Power Eastward Transmission Project, the company utilized ER50 series solid welding wire and H08A welding wire, selected for their superior strength and compatibility with the welding process. The primary welding equipment includes CO2 gas-shielded welding machines, advanced pipeline integration machines, and automated flange welding systems, all selected to ensure high-quality welds and operational efficiency.

Figure 5: CO2 Gas-Shielded Welding Machine

Figure 6: Pipeline Integration Machine

Figure 7: Automatic Flange Welding Machine

Through continuous optimization and improvement of welding processes, the company has positioned itself as a leader in steel pipe tower production. It has contributed to the construction of the 1,000kV Zhejiang-Fuzhou and 1,000kV Huaishang transmission lines and secured the contract for the 1,000kV Ximeng-Shandong steel pipe tower project. The company's commitment to 'building towers and creating landmarks' is demonstrated through its actions, and the team is ready to embrace future challenges.

Related News

- Installation of Main Bolts for Lap Joint Flange in High-Temperature Gas-Cooled Reactors

- Structural Design and Finite Element Analysis of Anchor Flanges

- Key Welding Technology for High-Neck Flange and Steel Pipe Joints

- The Design and Calculation of Stamped Lap Joint Flanges

- Development of Manufacturing Large Anchor Flanges

- Hardfacing the Inner Surface of Long-Neck Flanges Using CO₂ Gas-Shielded Welding

- UHV High-Neck Flange Welding

- Application of High-Neck Flange to UHV Steel Pipe Tower

- Analysis of the Cracking Cause of High-Neck Flanges

- Anchor Flanges for the East-West Gas Transmission Project