Internal Threads of Stainless Steel Flanges

Definition

The internal threads of stainless steel flanges are mechanical parts that connect pipes or equipment by means of threads. Internal threads of stainless steel flanges play an important role in various industrial piping systems. Their excellent performance and diverse applications make them the preferred connectors in many engineering projects.

Related standards

The manufacture and use of internal threads of stainless steel flanges need to follow relevant standards to ensure quality and safety. Common Standards include the ASME B16.5 (applicable to pipe flanges and flange accessories), DIN 2566 Standard and GB/T Standard such as GB/T 9112-2010, involving flange dimensions, materials, and other requirements.

Features

Stainless steel has excellent corrosion resistance and mechanical strength, enabling flanges made from this material to be used for a long time in corrosive environments without rusting or damage. The internally threaded flange is connected to the pipe or equipment by threads, making it easy to install and disassemble, which is suitable for piping systems that need to be frequently disassembled and maintained. The internally threaded flange is well connected by threads, and with a sealing gasket, it can achieve a good sealing effect to prevent leakage. The internal thread is widely used in pipeline systems in the petroleum, chemical, food, pharmaceutical, and other industries, and is especially suitable for small and medium-diameter pipelines.

Tensile strength tests of stainless steel flange internal threads

Test devices

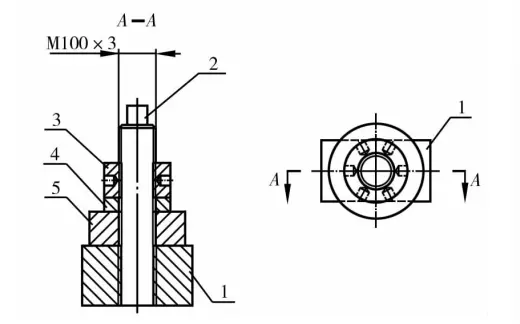

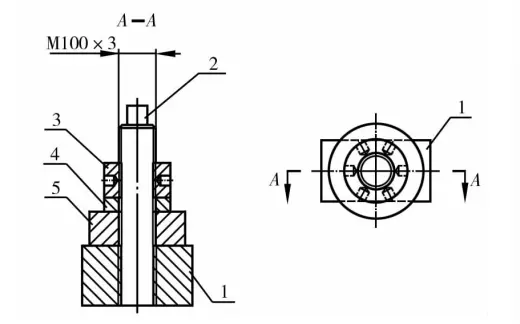

The test device consists of test bases (Z3CN20-09M), studs (35CrMoA), round nuts, washers, and stainless steel flanges (Figure 1).

1. Test bases 2. Studs 3. Round nuts 4. Washers 5. Flanges

Figure 1: The test device for tensile strength of stainless steel flange internal threads

Test processes

(1) Use the tensioner to slowly load the bolt. When the tensioner applies a pressure of 20MPa, record the corresponding tensile load acting on the bolt and the residual load after tightening the nut. Record the data once for every 20MPa increase in the tensioner pump pressure.

(2) When the tensioner pressure reaches 120MPa and the bolt residual load exceeds 160kN, maintain the pressure for 15 minutes. Then, reload the bolt, loosen the nut, remove the bolt, and inspect the base thread surface.

(3) Starting from the tensioner pump pressure reaching 120MPa, maintain the residual load for 15 minutes for every 20MPa increase in the tensioner pump pressure. Then, reload the bolt, loosen the nut, remove the bolt, and inspect the base thread surface.

(4) When the tensioner pump pressure reaches 180MPa, the bolt residual load exceeds 230kN. When the pressure is maintained for 4 hours, the bolt is reloaded, the nut is loosened, the bolt is removed, and the thread surface of the base is inspected.

Test result judgment

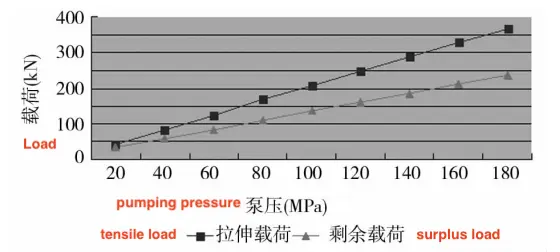

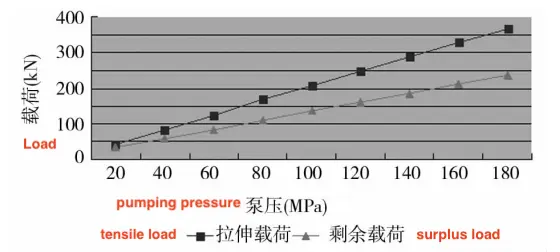

(1) The tensile load and residual load measured in the test are plotted as a curve ( Figure 2). It can be seen from the figure that the tensile and residual load curves are distributed in a linear shape, which means that the entire internal thread of the test base made from Z3CN20-09M is still within the elastic range and no obvious yield deformation occurs.

Figure 2: Bolt tensile and residual load curve

(2) When the tensioner pump pressure reaches 120MPa and the bolt residual load exceeds 160kN, after maintaining the pressure for 15 minutes, misalignment didn’t occur for the internal thread of the test base made from Z3CN20-09M after the plug gauge inspection.

(3) When the tensioner pump pressure reaches 180MPa, the residual load of the bolt exceeds 230kN. After maintaining the pressure for 4 hours, the threaded hole is checked with a through gauge. It is found that the upper and lower threads of the internal thread of the test base made from Z3CN20-09M can only be screwed in about 2 turns. After 24 hours, there is no change, indicating that the thread has undergone a slight yield deformation, but it does not affect the disassembly and assembly of the bolt pair.

The test results show that when the residual load on the bolt exceeds 230kN, maintaining the pressure for 24 hours does not affect the disassembly and assembly of the bolt. This shows that the internal thread of the test base made from Z3CN20-09M can meet the load requirements of the water pressure test, that is, the thread of the countersunk screw hole of the stainless steel flange can meet the load requirements of the water pressure test. The test also shows that in the calculation of the short-term thread static load, the coefficient of the allowable stress in the "Connection and Design Manual of Fasteners" can be appropriately enlarged. At the same time, this test provides a certain basis for the use of threads under short-term static loads.

The internal threads of stainless steel flanges are mechanical parts that connect pipes or equipment by means of threads. Internal threads of stainless steel flanges play an important role in various industrial piping systems. Their excellent performance and diverse applications make them the preferred connectors in many engineering projects.

Related standards

The manufacture and use of internal threads of stainless steel flanges need to follow relevant standards to ensure quality and safety. Common Standards include the ASME B16.5 (applicable to pipe flanges and flange accessories), DIN 2566 Standard and GB/T Standard such as GB/T 9112-2010, involving flange dimensions, materials, and other requirements.

Features

Stainless steel has excellent corrosion resistance and mechanical strength, enabling flanges made from this material to be used for a long time in corrosive environments without rusting or damage. The internally threaded flange is connected to the pipe or equipment by threads, making it easy to install and disassemble, which is suitable for piping systems that need to be frequently disassembled and maintained. The internally threaded flange is well connected by threads, and with a sealing gasket, it can achieve a good sealing effect to prevent leakage. The internal thread is widely used in pipeline systems in the petroleum, chemical, food, pharmaceutical, and other industries, and is especially suitable for small and medium-diameter pipelines.

Tensile strength tests of stainless steel flange internal threads

Test devices

The test device consists of test bases (Z3CN20-09M), studs (35CrMoA), round nuts, washers, and stainless steel flanges (Figure 1).

1. Test bases 2. Studs 3. Round nuts 4. Washers 5. Flanges

Figure 1: The test device for tensile strength of stainless steel flange internal threads

Test processes

(1) Use the tensioner to slowly load the bolt. When the tensioner applies a pressure of 20MPa, record the corresponding tensile load acting on the bolt and the residual load after tightening the nut. Record the data once for every 20MPa increase in the tensioner pump pressure.

(2) When the tensioner pressure reaches 120MPa and the bolt residual load exceeds 160kN, maintain the pressure for 15 minutes. Then, reload the bolt, loosen the nut, remove the bolt, and inspect the base thread surface.

(3) Starting from the tensioner pump pressure reaching 120MPa, maintain the residual load for 15 minutes for every 20MPa increase in the tensioner pump pressure. Then, reload the bolt, loosen the nut, remove the bolt, and inspect the base thread surface.

(4) When the tensioner pump pressure reaches 180MPa, the bolt residual load exceeds 230kN. When the pressure is maintained for 4 hours, the bolt is reloaded, the nut is loosened, the bolt is removed, and the thread surface of the base is inspected.

Test result judgment

(1) The tensile load and residual load measured in the test are plotted as a curve ( Figure 2). It can be seen from the figure that the tensile and residual load curves are distributed in a linear shape, which means that the entire internal thread of the test base made from Z3CN20-09M is still within the elastic range and no obvious yield deformation occurs.

Figure 2: Bolt tensile and residual load curve

(2) When the tensioner pump pressure reaches 120MPa and the bolt residual load exceeds 160kN, after maintaining the pressure for 15 minutes, misalignment didn’t occur for the internal thread of the test base made from Z3CN20-09M after the plug gauge inspection.

(3) When the tensioner pump pressure reaches 180MPa, the residual load of the bolt exceeds 230kN. After maintaining the pressure for 4 hours, the threaded hole is checked with a through gauge. It is found that the upper and lower threads of the internal thread of the test base made from Z3CN20-09M can only be screwed in about 2 turns. After 24 hours, there is no change, indicating that the thread has undergone a slight yield deformation, but it does not affect the disassembly and assembly of the bolt pair.

The test results show that when the residual load on the bolt exceeds 230kN, maintaining the pressure for 24 hours does not affect the disassembly and assembly of the bolt. This shows that the internal thread of the test base made from Z3CN20-09M can meet the load requirements of the water pressure test, that is, the thread of the countersunk screw hole of the stainless steel flange can meet the load requirements of the water pressure test. The test also shows that in the calculation of the short-term thread static load, the coefficient of the allowable stress in the "Connection and Design Manual of Fasteners" can be appropriately enlarged. At the same time, this test provides a certain basis for the use of threads under short-term static loads.

Next: Flanges Formed by Bending

Previous: Installation Guide for Threaded Flanges

Related News

- Installation of Main Bolts for Lap Joint Flange in High-Temperature Gas-Cooled Reactors

- Structural Design and Finite Element Analysis of Anchor Flanges

- Key Welding Technology for High-Neck Flange and Steel Pipe Joints

- The Design and Calculation of Stamped Lap Joint Flanges

- Development of Manufacturing Large Anchor Flanges

- Hardfacing the Inner Surface of Long-Neck Flanges Using CO₂ Gas-Shielded Welding

- UHV High-Neck Flange Welding

- Application of High-Neck Flange to UHV Steel Pipe Tower

- Analysis of the Cracking Cause of High-Neck Flanges

- Anchor Flanges for the East-West Gas Transmission Project