News

Industry News

Bolted Flanges

- Posted: 12/22/2021 04:12:02

- Hits: 46

Sealing by gaskets is the most important static sealing at the detachable joints of pressure vessels, process equipment, power machines and connecting pipes in industrial units. Their working conditions are very complex, and the range of media is quite wide. Preventing liquid or gas from...

Structure of Austenitic SS Bellows & F6NM Martensitic SS Flanges after Welding (Part Two)

- Posted: 12/08/2021 07:12:42

- Hits: 22

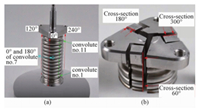

Observed the microstructure of the heat-affected zone, fusion zone and weld metal zone on the F6NM martensite flange side, as shown in Figure 5. In the as-welded state, the base metal and weld metal of the F6NM martensite flange side (Figure 5a) were well formed, and there were a...

Structure of Austenitic SS Bellows & F6NM Martensitic SS Flanges after Welding (Part One)

- Posted: 11/25/2021 01:11:43

- Hits: 51

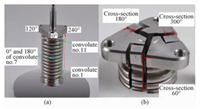

Abstract The microstructure and mechanical properties of the welded joints of 316Ti stainless steel bellows used for valves and F6NM martensitic stainless steel flanges in the as-welded state and post-weld heat treatment (PWHT) were studied in this article. The results showed that the...

Strength and Hardness of Metal Gaskets of Flanges

- Posted: 10/22/2021 10:10:18

- Hits: 210

In order to be resistant to corrosion in the atmosphere, if the flange is in an industrial atmosphere or a heavily polluted area, it needs to be cleaned in time to avoid corrosion. Stainless steel flanges are suitable for food processing, storage and transportation. In high-pressure equipment and...

The Manufacturing of Welding Flanges

- Posted: 09/24/2021 11:09:56

- Hits: 163

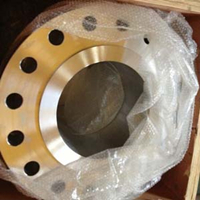

The welding process of the flange The welding process of the flange is to fix two pipes, pipe fittings or equipment on a welding first. Put a gasket between the two welds, and then use bolts to complete the connection. Welding is an important connection for the construction of...

The Processing Technology of SS 316L Flanges

- Posted: 07/12/2021 11:07:29

- Hits: 35

Abstract: In the processing of SS 316L flanges, certain problems are found in the first trial cutting piece, such as not being able to mass-produce due to low efficiency, and accuracy not meeting the standard. Analyze the causes of these problems, and then take...

Failures of Sealing of Flanges on the Top of the Cryogenic Tank's Pump Well (Part Three)

- Posted: 06/28/2021 11:06:23

- Hits: 83

3. Measures to avoid leakages at the flange's sealing surface of the pump well Leakage of the flange surface of the pump well will cause serious damage to the top of the low-temperature tank. The core of solving the problem of sealing leakage at the flange of the pump well is...

Failures of Sealing of Flanges on the Top of the Cryogenic Tank's Pump Well (Part Two)

- Posted: 06/07/2021 05:06:18

- Hits: 54

2. Reasons for the failure of the sealing surface of the top flange of the pump well Under normal circumstances, there are two forms of leakages on the flange's sealing surface: penetration leakages and interface leakages. When permeation leakage occurs, the fluid leaks through the capillary tube...

Failures of Sealing of Flanges on the Top of the Cryogenic Tank's Pump Well (Part One)

- Posted: 05/27/2021 12:05:22

- Hits: 71

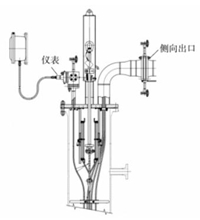

Abstract Flanges on the top of pump wells of cryogenic tanks not only are subjected to periodic pressure and temperature changes during the normal operation of the cryogenic tank, but also the vibration load of the pump during operation. If the design is unreasonable, it may cause the sealing of the...

The Importance of the Sealing of the Flange Connection at High Temperatures

- Posted: 04/28/2021 08:04:08

- Hits: 56

There are many detachable sealing connection forms for containers and pipes, such as threaded connections, socket connections, and flange connections. Among them, the flange connection is the most common in the industry due to its simple structure, easy assembly, and disassembly. The flange connection...

Leakages of stainless steel flanges in refrigeration units of petrochemical equipment

- Posted: 03/19/2021 03:03:39

- Hits: 33

Abstract there are often dangerous factors such as flammable, explosive, high temperature, high-pressure, cryogenic, toxic and harmful and corrosive factors in the petrochemical production, processing, storage and transportation. Because high temperature, high pressure and deep cold can improve production...

How to Tell whether the Stainless Steel Flange is Real?

- Posted: 02/21/2021 10:02:32

- Hits: 72

There are many stainless steel flanges on the market. How to tell whether the stainless steel flange is real? The following methods will be shared with you. The spot test 1. Nitric acid A remarkable feature of the stainless steel flange is its corrosion resistance to concentrated...