How to choose the materials of stainless steel flanges

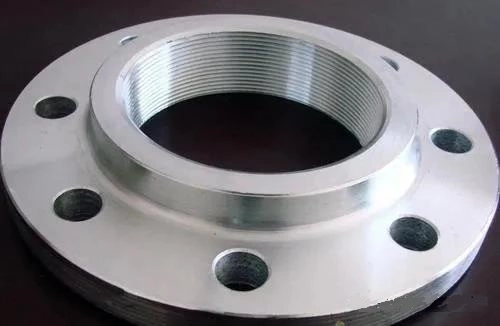

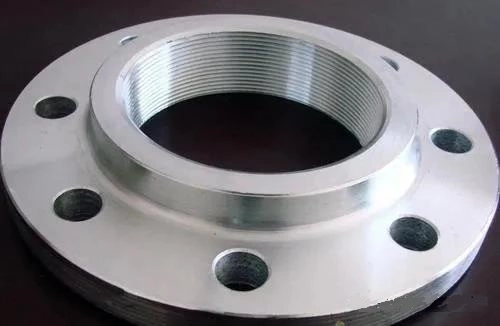

Flange is a disc-shaped connecting part that is connected between pipe ends and closed at the same time. It is the most common in pipeline engineering, such as the connection of ventilation pipes.

Flange materials include carbon steel, low alloy steel and stainless steel. Among them, stainless steel is the most commonly used. So what are the materials of stainless steel flanges? How to choose?

Stainless steel flanges are available in 316 stainless steel (CF8M), 347 stainless steel (CF8C), 304 stainless steel (CF8), 304L stainless steel (CF3), and 316L stainless steel (CF3M).

316 stainless steel (CF8M)

Corrosive or ultra-low temperature or high temperature non-corrosive applications;

Temperature range: -268 ℃ to +649 ℃, the temperature above +425 ℃ must specify a carbon content of 0.04% and above.

347 stainless steel (CF8C)

Mainly used in high temperature and corrosive applications;

Temperature range: -268 ℃ to +649 ℃, the temperature above +540 ℃ must specify a carbon content of 0.04% and above.

304 stainless steel (CF8)

Corrosive or ultra-low temperature or high temperature non-corrosive applications;

Temperature range: -268 ℃ to +649 ℃, the temperature above +425 ℃ must specify a carbon content of 0.04% and above.

304L stainless steel (CF3)

Corrosive or non-corrosive applications; the temperature range up to + 425 ℃.

316L stainless steel (CF3M)

Corrosive or non-corrosive applications, temperature range up to + 454 ℃.

Note: The above five kinds of stainless steel materials refer to ASTM A351, CF8M, CF8C, CF8, CF3, CF3M castings, which are often used as valve materials.

Flange materials include carbon steel, low alloy steel and stainless steel. Among them, stainless steel is the most commonly used. So what are the materials of stainless steel flanges? How to choose?

Stainless steel flanges are available in 316 stainless steel (CF8M), 347 stainless steel (CF8C), 304 stainless steel (CF8), 304L stainless steel (CF3), and 316L stainless steel (CF3M).

316 stainless steel (CF8M)

Corrosive or ultra-low temperature or high temperature non-corrosive applications;

Temperature range: -268 ℃ to +649 ℃, the temperature above +425 ℃ must specify a carbon content of 0.04% and above.

347 stainless steel (CF8C)

Mainly used in high temperature and corrosive applications;

Temperature range: -268 ℃ to +649 ℃, the temperature above +540 ℃ must specify a carbon content of 0.04% and above.

304 stainless steel (CF8)

Corrosive or ultra-low temperature or high temperature non-corrosive applications;

Temperature range: -268 ℃ to +649 ℃, the temperature above +425 ℃ must specify a carbon content of 0.04% and above.

304L stainless steel (CF3)

Corrosive or non-corrosive applications; the temperature range up to + 425 ℃.

316L stainless steel (CF3M)

Corrosive or non-corrosive applications, temperature range up to + 454 ℃.

Note: The above five kinds of stainless steel materials refer to ASTM A351, CF8M, CF8C, CF8, CF3, CF3M castings, which are often used as valve materials.

Related News

- Installation of Main Bolts for Lap Joint Flange in High-Temperature Gas-Cooled Reactors

- Structural Design and Finite Element Analysis of Anchor Flanges

- Key Welding Technology for High-Neck Flange and Steel Pipe Joints

- The Design and Calculation of Stamped Lap Joint Flanges

- Development of Manufacturing Large Anchor Flanges

- Hardfacing the Inner Surface of Long-Neck Flanges Using CO₂ Gas-Shielded Welding

- UHV High-Neck Flange Welding

- Application of High-Neck Flange to UHV Steel Pipe Tower

- Analysis of the Cracking Cause of High-Neck Flanges

- Anchor Flanges for the East-West Gas Transmission Project