Heat Treatment & Mechanical Properties of ASTM A350 LF3 Flanges (Part One)

Abstract

ASTM A350 LF3 steel blind flanges and butt-welded flanges of different sizes need to be tempered to meet the requirement for mechanical property. In addition to the chemical composition of the steel, to determine the appropriate tempering process, ASTM A350 LF3 steel test block I was used for heat treatment process tests, namely 900℃ air cooling normalizing, 880℃ water quenching and 650℃ tempering. As a result, the mechanical properties of test block I met the requirements, but the elongation after fracture was just qualified. For this reason, the tempering process of ASTM A350 LF3 steel test block II was adjusted to 850℃ water quenching and 670℃ tempering. The results show that the tensile properties and -101℃ impact toughness of test block II meet the requirements. After the two flanges were tempered by the adjusted process, the mechanical properties met the requirements.

Introduction

ASTM A350 LF3 steel pipeline flanges are essential components in the construction of pipelines, providing a secure connection between different sections of piping. These flanges are made from low-temperature carbon steel, specifically designed to withstand extreme temperatures and pressures commonly found in industrial applications. The ASTM A350 LF3 steel pipeline flanges offer excellent corrosion resistance and durability, making them ideal for use in harsh environments such as oil and gas refineries, chemical plants, and power generation facilities. Their high strength and reliability ensure that pipelines remain leak-free and operational for extended periods. Furthermore, these flanges are manufactured to meet strict industry standards set by the American Society for Testing and Materials (ASTM), guaranteeing their quality and performance. In conclusion, ASTM A350 LF3 steel pipeline flanges play a crucial role in ensuring the safe and efficient transportation of fluids through pipelines worldwide.

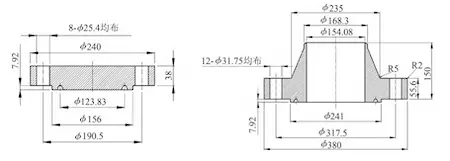

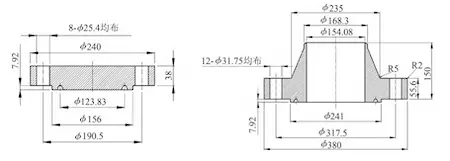

ASTM A350 LF3 is a steel grade in the ASTM A350 or A350M standard "Carbon steel and low alloy steel forgings with notch impact toughness for pipeline components". It has good ultra-low temperature impact performance (-101℃) and is widely used in petrochemical and other fields. A similar low-temperature steel in China is 08Ni3D steel in NB/T 47009-2010 "Low alloy steel forgings for low-temperature pressure equipment". A batch of A350 LF3CL1 pipeline flanges is manufactured, which belong to the 900-grade ring gasket joint blind flanges (as shown in Figure 1 (a), hereinafter referred to as blind flanges) and 900-grade ring gasket joint cone neck butt welding flanges (as shown in Figure 1 (b), hereinafter referred to as butt welding flanges) in the ASME B16.5-2013 standard "Pipe flanges and fittings". For this purpose, a series of heat treatment process tests were carried out, and finally, the mechanical properties of the flanges met the requirements.

1. A comparison of ASTM A350 LF3 and 08Ni3D steels

The chemical composition and requirements for mechanical properties of 08Ni3D and ASTM A350 LF3 steels are listed in Tables 1 and 2. It can be seen from Tables 1 and 2 that the chemical composition of 08Ni3D and ASTM A350 LF3 steels is the same; the carbon content of 08Ni3D steel is slightly lower; its requirement for strength is also slightly lower, and the low-temperature impact test temperature and the required impact absorption energy are slightly different. To ensure that the requirements of low-temperature impact performance can be met, the chemical composition of the steel is optimized. Increase the nickel content; appropriately reduce the carbon content; increase the manganese content, and reduce the phosphorus, sulfur and copper content as much as possible.

Figure 1 The schematic diagram of blind flanges (a) and butt welding flanges (b)

Table 1 Chemical composition of 08Ni3D and ASTM A350 LF3 steel %

ASTM A350 LF3 steel blind flanges and butt-welded flanges of different sizes need to be tempered to meet the requirement for mechanical property. In addition to the chemical composition of the steel, to determine the appropriate tempering process, ASTM A350 LF3 steel test block I was used for heat treatment process tests, namely 900℃ air cooling normalizing, 880℃ water quenching and 650℃ tempering. As a result, the mechanical properties of test block I met the requirements, but the elongation after fracture was just qualified. For this reason, the tempering process of ASTM A350 LF3 steel test block II was adjusted to 850℃ water quenching and 670℃ tempering. The results show that the tensile properties and -101℃ impact toughness of test block II meet the requirements. After the two flanges were tempered by the adjusted process, the mechanical properties met the requirements.

Introduction

ASTM A350 LF3 steel pipeline flanges are essential components in the construction of pipelines, providing a secure connection between different sections of piping. These flanges are made from low-temperature carbon steel, specifically designed to withstand extreme temperatures and pressures commonly found in industrial applications. The ASTM A350 LF3 steel pipeline flanges offer excellent corrosion resistance and durability, making them ideal for use in harsh environments such as oil and gas refineries, chemical plants, and power generation facilities. Their high strength and reliability ensure that pipelines remain leak-free and operational for extended periods. Furthermore, these flanges are manufactured to meet strict industry standards set by the American Society for Testing and Materials (ASTM), guaranteeing their quality and performance. In conclusion, ASTM A350 LF3 steel pipeline flanges play a crucial role in ensuring the safe and efficient transportation of fluids through pipelines worldwide.

ASTM A350 LF3 is a steel grade in the ASTM A350 or A350M standard "Carbon steel and low alloy steel forgings with notch impact toughness for pipeline components". It has good ultra-low temperature impact performance (-101℃) and is widely used in petrochemical and other fields. A similar low-temperature steel in China is 08Ni3D steel in NB/T 47009-2010 "Low alloy steel forgings for low-temperature pressure equipment". A batch of A350 LF3CL1 pipeline flanges is manufactured, which belong to the 900-grade ring gasket joint blind flanges (as shown in Figure 1 (a), hereinafter referred to as blind flanges) and 900-grade ring gasket joint cone neck butt welding flanges (as shown in Figure 1 (b), hereinafter referred to as butt welding flanges) in the ASME B16.5-2013 standard "Pipe flanges and fittings". For this purpose, a series of heat treatment process tests were carried out, and finally, the mechanical properties of the flanges met the requirements.

1. A comparison of ASTM A350 LF3 and 08Ni3D steels

The chemical composition and requirements for mechanical properties of 08Ni3D and ASTM A350 LF3 steels are listed in Tables 1 and 2. It can be seen from Tables 1 and 2 that the chemical composition of 08Ni3D and ASTM A350 LF3 steels is the same; the carbon content of 08Ni3D steel is slightly lower; its requirement for strength is also slightly lower, and the low-temperature impact test temperature and the required impact absorption energy are slightly different. To ensure that the requirements of low-temperature impact performance can be met, the chemical composition of the steel is optimized. Increase the nickel content; appropriately reduce the carbon content; increase the manganese content, and reduce the phosphorus, sulfur and copper content as much as possible.

Figure 1 The schematic diagram of blind flanges (a) and butt welding flanges (b)

Table 1 Chemical composition of 08Ni3D and ASTM A350 LF3 steel %

| Grades | C | Si | Mn | P | S | Ni |

| 08Ni3D | Less than and equal to 0.1 | 0.15 to 0.35 | 0.4 to 0.9 | Less than and equal to 0.015 | Less than and equal to 0.01 | 3.3 to 3.7 |

| ASTM A350 LF3 | Less than and equal to 0.2 | 0.2 to 0.35 | Less than and equal to 0.9 | Less than and equal to 0.035 | Less than and equal to 0.04 | 3.3 to 3.7 |

| Optimized ASTM A350 LF3 | 0.14 to 0.18 | 0.2 to 0.35 | 0.6 to 0.9 | Less than and equal to 0.08 | Less than and equal to 0.05 | 3.5 to 3.7 |

| Grades | Cr | Mo | V | Cu | Nb | Cr plus Mo |

| 08Ni3D | Less than and equal to 0.3 | Less than and equal to 0.12 | Less than and equal to 0.03 | Less than and equal to 0.25 | Less than and equal to 0.02 | - |

| ASTM A350 LF3 | Less than and equal to 0.3 | Less than and equal to 0.12 | Less than and equal to 0.03 | Less than and equal to 0.4 | Less than and equal to 0.02 | Less than and equal to 0.32 |

| Optimized ASTM A350 LF3 | Less than and equal to 0.2 | Less than and equal to 0.12 | Less than and equal to 0.03 | Less than and equal to 0.2 | Less than and equal to 0.02 | Less than and equal to 0.32 |

Table 2 Mechanical properties requirements of 08Ni3D and A350 LF3 steels

| Grades | Re/MPa | Rm/MPa | A/( %) | Z/( %) | AKV/J |

| 08Ni3D | Greater than and equal to 260 | 460 to 610 | Greater than and equal to 22 | - | -100℃, Greater than and equal to 47 |

| ASTM A350 LF3 | Greater than and equal to 260 | 485 to 655 | Greater than and equal to 22 | Greater than and equal to 30 | -101℃, Greater than and equal to 20 |

2. Manufacturing processes of low-temperature pipeline flanges

According to the shape and size, different processes are used to manufacture the two flanges. The manufacturing process of blind flange is as follows: steel ingots → blanking → free forging → normalizing → quenching plus tempering → fine turning; the manufacturing process of butt welding flanges is steel ingots → electro-hydraulic hammer forging → upsetting → normalizing → rough turning → quenching plus tempering → fine turning.

Related News

- Low-Temperature Flange Sealing Solutions for Cryogenic Chemical Pipelines

- Innovative Technology for Automatic Alignment in Underwater Flange Assembly

- Stamped Steel Slip-On Flanges

- Design and Finite Element Analysis of Anchor Flanges for Oil & Gas Pipelines

- Forming and Manufacturing Technology of Anchor Flanges

- Structure and Materials of Anchor Flanges

- Flanges for Pressure Vessels

- An Introduction to Socket Welded Neck Flanges

- Heat Treatment & Mechanical Properties of ASTM A350 LF3 Flanges (Part Two)

- Heat Treatment & Mechanical Properties of ASTM A350 LF3 Flanges (Part One)