Causes of Cracks in 304 Stainless Steel Pipe Fittings

Stainless steel 304 has good heat resistance, corrosion resistance, cold and hot processing and welding, and is widely used in high-temperature corrosion parts of oil refining and chemical equipment, which is very important to ensure the safe operation of the equipment. During the inspection of a new device, it was found that there were many cracks in stainless steel 304 pipe fittings such as flanges, elbows and tees, which seriously affected the safe operation of the device. To analyze the cause and mechanism of cracks in stainless steel 304 pipe fittings and eliminate hidden dangers, two flanges with penetrating cracks were dissected, sampled, tested and analyzed, and surface flaw detection, metallographic inspection and hardness testing were carried out on other parts. According to the comprehensive analysis, the solution heat treatment of the pipe fittings does not meet the requirements, the metallographic structure has uneven austenite structure, chromium carbide precipitates, and the precipitates are distributed in granular, banded, and chain shapes; there are suspected cracks, leading to the generation and expansion of cracks. For pipe fittings with no cracks on the outer surface, there is also the possibility of cracks on the inner surface or cracks recurring during operation, which must be handled carefully.

1. Surface inspection for stainless steel pipe fittings

1.1 Penetrant inspection for external surfaces

A total of 27 pipelines were detected, and the total number of flanges detected was 311 pieces. According to NBT47013.5 "Nondestructive Testing. Penetrant Testing", a total of 14 pieces of problematic pipe fittings were detected, including 9 flanges, 3 reducers, 1 tee and 1 elbow. For example, cracks are found at the flange side, base metal and near the welding seam (Figure 1).

1.2 Metallographic inspection

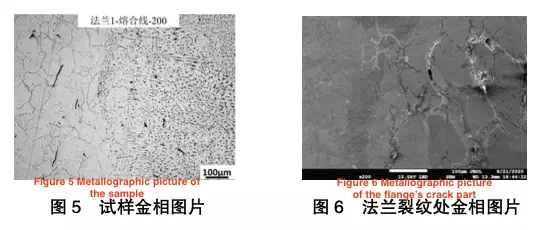

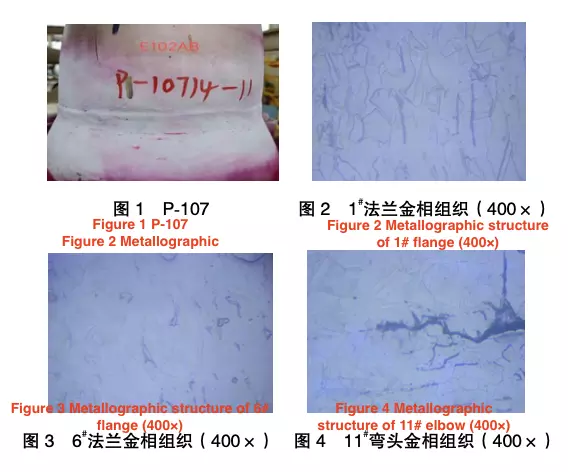

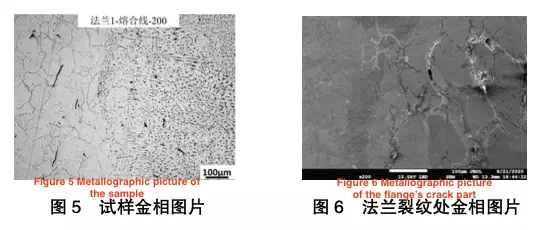

A total of 11 pipeline flanges and elbows were tested, numbered 1 to 11# in sequence. The on-site metallographic inspection was carried out according to the requirements of GBT 17455-2008 "Metallographic Replica Technology for Nondestructive Testing Surface Inspection". The inspection results are shown in Table 1 and Figures 2 to 4. The metallographic structure of the flange is austenite plus precipitated phases, and the precipitated phases are distributed in granular, banded, and chain shapes. Among them, there are suspected cracks around the precipitated phases in the 11#.

1.3 Hardness tests

According to the standard GB/T 20878-2007, the Brinell hardness value of stainless steel 304 is less than and equal to 201. The test results are within the acceptable range. The hardness test results are shown in Table 1.

Table 1 Metallographic test results

1.4 Other inspections

Ferromagnetic inspection is conducted with a magnet for all stainless steel 304 flanges, showing strong ferromagnetism and an abnormal austenite structure.

2. Chemical composition

According to the standard GB/T 20878-2007, the standard values of the composition of stainless steel 304 are shown in Table 2.

Four samples of flanges with through cracks were taken for testing, and the results are shown in Table 2.

Comparing the test average value with the standard components, each composition in the sample is similar to the standard value, and Mn is about 0.57 lower than the standard value.

Table 2 Test values of the composition of the sample

3. Metallographic inspection of two flanges with penetrating cracks

The base metal structure is relatively fine and uniform, but there are many precipitated phases on the grain boundaries. According to EDS analysis, the precipitated phases are Cr-rich phases, which may be Cr23C6 carbides. There are some black strips at the grain boundary of the base metal under the optical microscope. According to the SEM analysis, this type of strip is a microcrack generated along the grain boundary. The metallographic photos of the sample’s welding seam and the base metal are shown in Figure 5. The main cracks and secondary cracks are all intergranular cracks, and the metallographic photos of the cracks are shown in Figure 6.

Figure 5 Metallographic picture of the sample

Figure 6 Metallographic picture of the flange’s crack part

4. The analysis of cracks in stainless steel 304 pipe fittings

1) It can be obtained from the metallographic photograph that the base metal structure is typical single-phase austenite structure, and there are many elongated strip microcracks in the metallographic picture. There are many precipitated phases on the grain boundaries of the base metal structure. According to EDS analysis, the precipitated phases are Cr-rich phases, which may be Cr23C6 carbides.

2) The microstructure of the surfacing welding seam is columnar grain austenite, and the austenite columnar grain will be deformed to a certain extent near the fusion line.

3) According to the metallographic photograph of the crack section, it is preliminarily judged that the cracking is intergranular crack. There are a large number of carbon-rich substances (about 70%) and precipitated phases at the grain boundaries between the cracks.

4) Stainless steel 304 flanges are supplied with solid solution treatment according to current product standards. The metallographic structure of the flange is austenite plus the precipitated phase. If solid solution treatment is carried out according to the standard requirements, the precipitated phase should be absorbed.

5) Ferrite mainly exists in the precipitated phase with a large amount, so the flange shows strong ferromagnetism.

6) The chemical composition and hardness test meet requirements of the standard.

According to the above inspection and analysis, the stainless steel 304 pipe fittings have not been solid solution treated according to the requirement of the standard, and there are a large number of precipitated phases in the metallographic structure. The precipitated phases are distributed in the form of particles, bands, and chains. The presence of suspected cracks around the precipitated phase is the main factor for the generation and propagation of cracks.

5. Recommendations

1) After the stainless steel 304 pipe fittings are installed (not put into production), there is a possibility of cracks at room temperature.

2) The solid solution treatment is not sufficient, and there are many precipitated phases on the grain boundaries of the austenite structure, which is the main reason for the occurrence and development of cracks in stainless steel 304 pipe fittings.

1. Surface inspection for stainless steel pipe fittings

1.1 Penetrant inspection for external surfaces

A total of 27 pipelines were detected, and the total number of flanges detected was 311 pieces. According to NBT47013.5 "Nondestructive Testing. Penetrant Testing", a total of 14 pieces of problematic pipe fittings were detected, including 9 flanges, 3 reducers, 1 tee and 1 elbow. For example, cracks are found at the flange side, base metal and near the welding seam (Figure 1).

1.2 Metallographic inspection

A total of 11 pipeline flanges and elbows were tested, numbered 1 to 11# in sequence. The on-site metallographic inspection was carried out according to the requirements of GBT 17455-2008 "Metallographic Replica Technology for Nondestructive Testing Surface Inspection". The inspection results are shown in Table 1 and Figures 2 to 4. The metallographic structure of the flange is austenite plus precipitated phases, and the precipitated phases are distributed in granular, banded, and chain shapes. Among them, there are suspected cracks around the precipitated phases in the 11#.

1.3 Hardness tests

According to the standard GB/T 20878-2007, the Brinell hardness value of stainless steel 304 is less than and equal to 201. The test results are within the acceptable range. The hardness test results are shown in Table 1.

Table 1 Metallographic test results

| Items | Pipelines | Metallographic structure | Figures | Hardness values |

| 1# | P1603-4 | Austenite plus precipitated phases, the precipitated phases are granular, banded, and chain-like. | Figure 2 | 150, 154 and 154 |

| 2# | P10615-4 | Austenite plus precipitated phases, the precipitated phases are granular, banded, and chain-like. | 141, 144 and 145 | |

| 3# | P10702-1 | Austenite plus precipitated phases, the precipitated phases are granular, banded, and chain-like. | 150, 145 and 141 | |

| 4# | P10705-2 | Austenite plus precipitated phase, the precipitated phase is granular. | 156, 158 and 154 | |

| 5# | P10705-2 | Austenite plus precipitated phase, the precipitated phase is granular. | 143, 145 and 146 | |

| 6# | P10712-3 | Austenite plus precipitated phase, the precipitated phase is granular. | Figure 3 | 149, 150 and 160 |

| 7# | P10712-2 | Austenite plus precipitated phase, the precipitated phase is granular. | 135, 139 and 140 | |

| 8# | P10712 (elbows) | Austenite plus precipitated phase, the precipitated phase is granular. | 130, 125 and 137 | |

| 9# | P10611 | Austenite plus precipitated phase, the precipitated phase is granular. | 160, 185 and 182 | |

| 10# | P20412-1 | Austenite plus precipitated phase, the precipitated phase is granular. | 141, 145 and 150 | |

| 11# | P10611-1 | Austenite plus precipitated phase, the precipitates are distributed in granular, banded, and chain shapes, and there are suspected cracks around the precipitates. | Figure 4 | 141, 150 and 139 |

1.4 Other inspections

Ferromagnetic inspection is conducted with a magnet for all stainless steel 304 flanges, showing strong ferromagnetism and an abnormal austenite structure.

2. Chemical composition

According to the standard GB/T 20878-2007, the standard values of the composition of stainless steel 304 are shown in Table 2.

Four samples of flanges with through cracks were taken for testing, and the results are shown in Table 2.

Comparing the test average value with the standard components, each composition in the sample is similar to the standard value, and Mn is about 0.57 lower than the standard value.

Table 2 Test values of the composition of the sample

| Items | C | Si | Mn | P | S | Cr | Mo | Ni | Cu | Fe |

| Average values | 0.081 | 0.85 | 1.43 | 0.036 | 0.0035 | 18.03 | 0.065 | 8.015 | 0.330 | 70.21 |

| Standard values | 0.080 | 1.00 | 2.00 | 0.050 | 0.0300 | 18.8-20.0 | / | 8.0 to 11.0 | / | / |

3. Metallographic inspection of two flanges with penetrating cracks

The base metal structure is relatively fine and uniform, but there are many precipitated phases on the grain boundaries. According to EDS analysis, the precipitated phases are Cr-rich phases, which may be Cr23C6 carbides. There are some black strips at the grain boundary of the base metal under the optical microscope. According to the SEM analysis, this type of strip is a microcrack generated along the grain boundary. The metallographic photos of the sample’s welding seam and the base metal are shown in Figure 5. The main cracks and secondary cracks are all intergranular cracks, and the metallographic photos of the cracks are shown in Figure 6.

Figure 5 Metallographic picture of the sample

Figure 6 Metallographic picture of the flange’s crack part

4. The analysis of cracks in stainless steel 304 pipe fittings

1) It can be obtained from the metallographic photograph that the base metal structure is typical single-phase austenite structure, and there are many elongated strip microcracks in the metallographic picture. There are many precipitated phases on the grain boundaries of the base metal structure. According to EDS analysis, the precipitated phases are Cr-rich phases, which may be Cr23C6 carbides.

2) The microstructure of the surfacing welding seam is columnar grain austenite, and the austenite columnar grain will be deformed to a certain extent near the fusion line.

3) According to the metallographic photograph of the crack section, it is preliminarily judged that the cracking is intergranular crack. There are a large number of carbon-rich substances (about 70%) and precipitated phases at the grain boundaries between the cracks.

4) Stainless steel 304 flanges are supplied with solid solution treatment according to current product standards. The metallographic structure of the flange is austenite plus the precipitated phase. If solid solution treatment is carried out according to the standard requirements, the precipitated phase should be absorbed.

5) Ferrite mainly exists in the precipitated phase with a large amount, so the flange shows strong ferromagnetism.

6) The chemical composition and hardness test meet requirements of the standard.

According to the above inspection and analysis, the stainless steel 304 pipe fittings have not been solid solution treated according to the requirement of the standard, and there are a large number of precipitated phases in the metallographic structure. The precipitated phases are distributed in the form of particles, bands, and chains. The presence of suspected cracks around the precipitated phase is the main factor for the generation and propagation of cracks.

5. Recommendations

1) After the stainless steel 304 pipe fittings are installed (not put into production), there is a possibility of cracks at room temperature.

2) The solid solution treatment is not sufficient, and there are many precipitated phases on the grain boundaries of the austenite structure, which is the main reason for the occurrence and development of cracks in stainless steel 304 pipe fittings.

Related News

- Installation of Main Bolts for Lap Joint Flange in High-Temperature Gas-Cooled Reactors

- Structural Design and Finite Element Analysis of Anchor Flanges

- Key Welding Technology for High-Neck Flange and Steel Pipe Joints

- The Design and Calculation of Stamped Lap Joint Flanges

- Development of Manufacturing Large Anchor Flanges

- Hardfacing the Inner Surface of Long-Neck Flanges Using CO₂ Gas-Shielded Welding

- UHV High-Neck Flange Welding

- Application of High-Neck Flange to UHV Steel Pipe Tower

- Analysis of the Cracking Cause of High-Neck Flanges

- Anchor Flanges for the East-West Gas Transmission Project