Bolted Flanges

Sealing by gaskets is the most important static sealing at the detachable joints of pressure vessels, process equipment, power machines and connecting pipes in industrial units. Their working conditions are very complex, and the range of media is quite wide. Preventing liquid or gas from leaking through these connections is the most important and difficult task faced by the factory. Although the leakage rate of flanges is not as high as that of the sealing of valve stems and agitators, the number of flanges is much more than them. Therefore, flanges have become the main source of leakage for process equipment. The environmental pollution and product loss caused by leakage make the importance of the sealing of the gasket self-evident.

The application range of gaskets is extremely wide, and the pre-tightening load required for gaskets is also different. For example, gaskets for low-pressure water pump thin flanges require lower compression loads, while pressure vessels and pipeline flanges need connections with greater compaction loads and rigidity. For gaskets with special needs, there are no standard connection dimensions, such as flange thickness, bolt sizes and bolt spacing, which requires special design. The connection of bolted flanges is the most important connection between process equipment and pipelines. This connection is affected by medium pressure, additional loads and vibration environment under operating conditions. The vibration characteristics of the structure will change, and leakage is the main reason for structural failures. When the bolt force of the connection structure changes, the sealing performance of the gasket and the dynamic characteristics of the structure will change. Analyzing the relationship between the sealing performance and dynamic characteristics of the connection system is of great significance to the research of the flange's sealing performance testing.

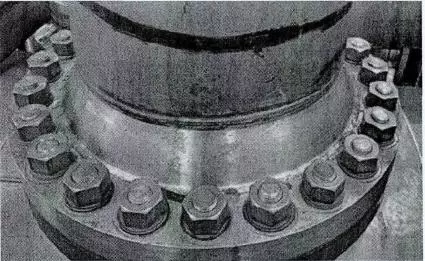

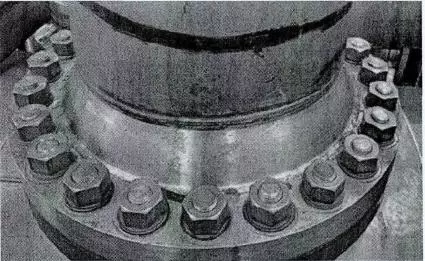

At present, the rapid development of a lot of modern industrial equipment and production equipment makes related equipment also develop in the direction of large-scale and high-speed accordingly. When mechanical equipment is operating under a complex vibration environment for a long time, especially pressure vessels and pipelines, it will inevitably affect the connection status of flanges and the sealing status of gaskets, such as leakages of gaskets and loose bolts. If they are not dealt with in time, the connection will fail, which in turn leads to the loss of structure and functions. As a simple and common connection in the structure of mechanical equipment, bolted flanges are widely used in the connection of complex engineering in the fields of nuclear power, aviation and chemical machinery. Common bolted flanges are composed of three parts: gaskets, components of bolts and flanges (as shown in Figure 1).

Figure 1 Bolted flanges

Common bolted flanges are divided into two connection methods. One is the non-contact bolt flange between metals, which is also called the floating type joint; the other is the contact type bolt flange between metals. For floating joints, all bolt loads act on the contact surface of the flange sealing surface and gasket. Part of the plastic deformation of the gasket is used to fill the macro and micro defects of the sealing surface to block the leakage of the medium on the flange sealing surface. However, when there is pressure fluctuation, if the deformation of the gasket is not adjusted properly, the looseness of the gasket will increase, thereby increasing the risk of leakage of the bolted flanges. In the MMC type of bolted flange joints, a distance block is arranged between the sealing surface of the flange or the gasket has a restriction ring. When metal to metal contact happens for flanges and the distance block or restriction rings of gaskets, only part of the bolt load acts on the gasket to form the sealing pressure of gaskets. The remaining bolt load is transferred to the gasket to compensate for its stress loss caused by external loads and internal pressure.

The bolted flange structure under different external excitation transmits force through frictions between the components of the connection structure. This makes the bolt connection gradually loosen, which will have a certain impact on the rigidity of the connection structure and the sealing of the gasket. In the whole structure, the rigidity of the bolted flange structure is weak, and the connection state is easy to change, which may cause the failure of the overall structure and a catastrophic accident. On August 20, 2007, a plane from China Airlines exploded and caught fire. The fire's starting point was at the front flap of the right main wing, and a set of metal bolts responsible for the swing of the front flap fell. This set of dropped metal bolts pierced the fuel tank of the right main wing at the rear due to the intense vibration during the landing, causing a large amount of fuel to leak from the fuel tank on the right and a fire, as shown in the picture 2.

Figure 2 The explosion of the plane

For this reason, for bolt loosening with different degrees, the sealing of the flange can be identified in time and accurately to provide the complete diagnostic information of the system according to the changes of structural dynamic parameters. Therefore, monitoring the bolted flange under the vibration environment and proposing an effective method for identifying the sealing state is of great significance.

The application range of gaskets is extremely wide, and the pre-tightening load required for gaskets is also different. For example, gaskets for low-pressure water pump thin flanges require lower compression loads, while pressure vessels and pipeline flanges need connections with greater compaction loads and rigidity. For gaskets with special needs, there are no standard connection dimensions, such as flange thickness, bolt sizes and bolt spacing, which requires special design. The connection of bolted flanges is the most important connection between process equipment and pipelines. This connection is affected by medium pressure, additional loads and vibration environment under operating conditions. The vibration characteristics of the structure will change, and leakage is the main reason for structural failures. When the bolt force of the connection structure changes, the sealing performance of the gasket and the dynamic characteristics of the structure will change. Analyzing the relationship between the sealing performance and dynamic characteristics of the connection system is of great significance to the research of the flange's sealing performance testing.

At present, the rapid development of a lot of modern industrial equipment and production equipment makes related equipment also develop in the direction of large-scale and high-speed accordingly. When mechanical equipment is operating under a complex vibration environment for a long time, especially pressure vessels and pipelines, it will inevitably affect the connection status of flanges and the sealing status of gaskets, such as leakages of gaskets and loose bolts. If they are not dealt with in time, the connection will fail, which in turn leads to the loss of structure and functions. As a simple and common connection in the structure of mechanical equipment, bolted flanges are widely used in the connection of complex engineering in the fields of nuclear power, aviation and chemical machinery. Common bolted flanges are composed of three parts: gaskets, components of bolts and flanges (as shown in Figure 1).

Figure 1 Bolted flanges

Common bolted flanges are divided into two connection methods. One is the non-contact bolt flange between metals, which is also called the floating type joint; the other is the contact type bolt flange between metals. For floating joints, all bolt loads act on the contact surface of the flange sealing surface and gasket. Part of the plastic deformation of the gasket is used to fill the macro and micro defects of the sealing surface to block the leakage of the medium on the flange sealing surface. However, when there is pressure fluctuation, if the deformation of the gasket is not adjusted properly, the looseness of the gasket will increase, thereby increasing the risk of leakage of the bolted flanges. In the MMC type of bolted flange joints, a distance block is arranged between the sealing surface of the flange or the gasket has a restriction ring. When metal to metal contact happens for flanges and the distance block or restriction rings of gaskets, only part of the bolt load acts on the gasket to form the sealing pressure of gaskets. The remaining bolt load is transferred to the gasket to compensate for its stress loss caused by external loads and internal pressure.

The bolted flange structure under different external excitation transmits force through frictions between the components of the connection structure. This makes the bolt connection gradually loosen, which will have a certain impact on the rigidity of the connection structure and the sealing of the gasket. In the whole structure, the rigidity of the bolted flange structure is weak, and the connection state is easy to change, which may cause the failure of the overall structure and a catastrophic accident. On August 20, 2007, a plane from China Airlines exploded and caught fire. The fire's starting point was at the front flap of the right main wing, and a set of metal bolts responsible for the swing of the front flap fell. This set of dropped metal bolts pierced the fuel tank of the right main wing at the rear due to the intense vibration during the landing, causing a large amount of fuel to leak from the fuel tank on the right and a fire, as shown in the picture 2.

Figure 2 The explosion of the plane

For this reason, for bolt loosening with different degrees, the sealing of the flange can be identified in time and accurately to provide the complete diagnostic information of the system according to the changes of structural dynamic parameters. Therefore, monitoring the bolted flange under the vibration environment and proposing an effective method for identifying the sealing state is of great significance.

Related News

- Installation of Main Bolts for Lap Joint Flange in High-Temperature Gas-Cooled Reactors

- Structural Design and Finite Element Analysis of Anchor Flanges

- Key Welding Technology for High-Neck Flange and Steel Pipe Joints

- The Design and Calculation of Stamped Lap Joint Flanges

- Development of Manufacturing Large Anchor Flanges

- Hardfacing the Inner Surface of Long-Neck Flanges Using CO₂ Gas-Shielded Welding

- UHV High-Neck Flange Welding

- Application of High-Neck Flange to UHV Steel Pipe Tower

- Analysis of the Cracking Cause of High-Neck Flanges

- Anchor Flanges for the East-West Gas Transmission Project