Applications of Flat Welding Flanges

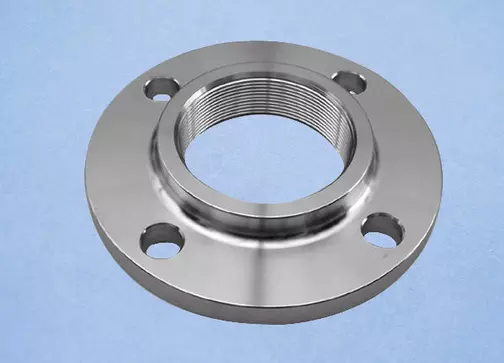

Flat welding flange is a connecting device between two large diameter pipelines, usually fastened by two flange gaskets with several bolts. Flat welding flange is a kind of cast steel flanges in common use. Low carbon steels are characterized by good plasticity and low strength, but, if added with appropriate amount of carbons, they will become rigid, reduce plasticity and enhance strength. The flange with such carbon steel materials can be called carbon steel flange.

Large flat welding flange is preferably chosen, because it may need to bear high tensile strength, compression strength, torsional strength and shear strength. Flat welding flange is usually applied in pipelines. If bolts are loosened, two pipelines can be rotated or easily dismantled.

The connection of flat welding flange is the simplest connection between cast iron pipes or between steel pipes, while blank flange is just used for inspection opening. The connection of flanges applies to such connection of pipeline fittings with the pipe diameter of 50~315mm, characterized by non-rigid connection, easy dismantlement and tensile resistance. Flanges are usually used as easily-dismantled connecting devices for low pressure transmission pipelines.

With the rapid development of long-distance pipeline industry, pressure testing for pipelines is a indispensable process before using flat welding flanges. Before pressure testing, pipeline pigging should be conducted four to five times for each pipeline. Especially after pressure testing, accumulated water in pipelines are not easy to clean, so more cleaning times are needed. Repeatedly welding the head of pipelines after pipeline pigging cause some problems, like the enhancement of workers’ labour intensity, high consumption of materials, and more times and high cost of using large equipment.

Large flat welding flange is preferably chosen, because it may need to bear high tensile strength, compression strength, torsional strength and shear strength. Flat welding flange is usually applied in pipelines. If bolts are loosened, two pipelines can be rotated or easily dismantled.

The connection of flat welding flange is the simplest connection between cast iron pipes or between steel pipes, while blank flange is just used for inspection opening. The connection of flanges applies to such connection of pipeline fittings with the pipe diameter of 50~315mm, characterized by non-rigid connection, easy dismantlement and tensile resistance. Flanges are usually used as easily-dismantled connecting devices for low pressure transmission pipelines.

With the rapid development of long-distance pipeline industry, pressure testing for pipelines is a indispensable process before using flat welding flanges. Before pressure testing, pipeline pigging should be conducted four to five times for each pipeline. Especially after pressure testing, accumulated water in pipelines are not easy to clean, so more cleaning times are needed. Repeatedly welding the head of pipelines after pipeline pigging cause some problems, like the enhancement of workers’ labour intensity, high consumption of materials, and more times and high cost of using large equipment.

Related News

- Stamped Steel Slip-On Flanges

- Design and Finite Element Analysis of Anchor Flanges for Oil & Gas Pipelines

- Forming and Manufacturing Technology of Anchor Flanges

- Structure and Materials of Anchor Flanges

- Flanges for Pressure Vessels

- An Introduction to Socket Welded Neck Flanges

- Heat Treatment & Mechanical Properties of ASTM A350 LF3 Flanges (Part Two)

- Heat Treatment & Mechanical Properties of ASTM A350 LF3 Flanges (Part One)

- High-pressure Wellhead Device Valve Body End Threaded Flanges

- Threaded Flanges at the End of Valve Bodies of High-pressure Oil & Gas Wellhead Devices