Application of High-Neck Flange to UHV Steel Pipe Tower

On this page

The high-neck flange, also known as a long-neck flange or neck flange, is a disc-shaped component primarily used to connect pipes. It has been widely applied in petrochemical, urban water supply, and power systems. In recent years, with the planning and construction of the UHV transmission line project by the Chinese Grid, the demand for UHV steel pipe towers has increased dramatically. The high-neck flange, used as a new connection form for steel pipe towers, has been proven to offer certain advancements and reliability, playing a vital role in enhancing the production capacity and quality of steel pipe towers.

The high-neck flange, as an integral flange with a tall neck, significantly enhances flange stiffness and load-bearing capacity. It is well-suited for assembly line and automated production, greatly enhancing the efficiency of component assembly and welding. Compared to the flat flange and steel pipe plug-in connection, it reduces welding material consumption, significantly lowers welding workload and labor costs, reduces welding stress, and resists structural deformation. Additionally, the high-neck flange is more convenient for on-site installation, as it eliminates concerns about abrasion of welding seams, making it a preferred choice.

The long-neck flange has a tall, thin neck and a significant difference between the upper and lower sections, making it challenging to form. Currently, long-neck flanges are primarily produced using sand casting and forging, but those used for UHV steel pipe towers are exclusively produced by forging to meet high strength. Additionally, compared to flat flanges, the asymmetric axial shape of long-neck flanges makes them more challenging to transfer, package, and transport.

Currently, the common flange types for UHV include flat flexible flanges, flat rigid flanges, high-neck flat welding flanges, and high-neck butt welding flanges. High-neck butt welding flanges are further classified into three types based on groove design: inner straight outer slope, outer straight inner slope, and inner and outer variable slope. Each flange type varies in steel consumption, processing complexity, welding difficulty with steel pipes, resistance to welding deformation, and internal defect detection rates. See Table 1 for details.

Table 1 Differences in common flange forms

Table 1 Differences in common flange forms

| Flange Form | Steel Consumption | Processing Difficulty | Welding with Steel Pipe Difficulty | Automation Feasibility | Internal Welding Joint Defect Detection Rate | Welding Deformation |

| High-neck butt welding flange (straight inside, slope outside) | Medium | Relatively easy | Easy to automate | High efficiency | High defect detection rate | The flange is not easy to deform. |

| High-neck butt welding flange (straight outside, slope inside) | Medium | Relatively easy | Can be automated | High efficiency | High defect detection rate | The flange is not easy to deform. |

| High-neck butt welding flange (variable slope inside and outside) | Less | Difficult | Can be automated | One-side inspection only | Low defect detection rate with one side | The flange is not easy to deform. |

| High-neck flat welding flange | Medium | Relatively easy | Not highly automated | Inspection difficulty | Low defect detection rate with difficult inspection | The flange is not easy to deform. |

| Plane stiffening rigid flange | High | Easy | Large welding volume, not easy to automate | Unable to inspect | Not being able to inspect | The flange is easy to deform due to great residual stress. |

| Plane flexible flange | Less | Easy | Difficult to weld, large deformation | Difficult to inspect | detection rate with difficult inspection |

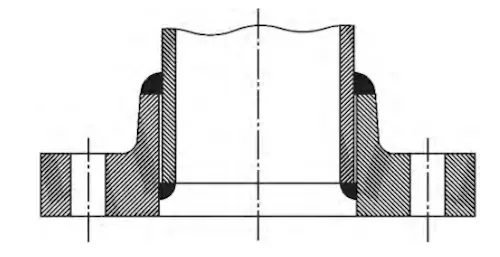

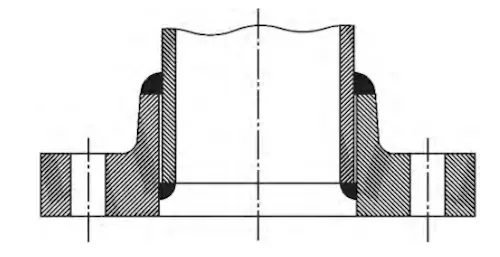

The connection between the long-neck flat-weld flange and the steel pipe is a new form of connection in the design of steel pipe towers in China, as shown in Figure 1, with the following advantages:

(1) Due to the large insertion depth of the steel pipe, the connection strength is higher than that of the T-joint between the flat flange and the steel pipe.

(2) Compared with the flat flange, the circumferential weld of the high-neck flat-weld flange facilitates welding automation; specifically, its corner weld can utilize GMAW (gas metal arc welding with argon-rich mixed shielding gas) at the flat position.

Figure 1 Connection form of high-neck flat-weld flange and steel pipe

The connection between the high-neck flat-weld flange and the steel pipe also has the following disadvantages:

(1) Due to the large insertion depth of the steel pipe, the connection strength is higher than that of the T-joint between the flat flange and the steel pipe.

(2) Compared with the flat flange, the circumferential weld of the high-neck flat-weld flange facilitates welding automation; specifically, its corner weld can utilize GMAW (gas metal arc welding with argon-rich mixed shielding gas) at the flat position.

Figure 1 Connection form of high-neck flat-weld flange and steel pipe

The connection between the high-neck flat-weld flange and the steel pipe also has the following disadvantages:

(1) Due to the structural shape limitations of the component, the steel pipe can only be placed horizontally during welding, which positions the weld leg on the side of the steel pipe; this setup makes the weld leg of the corner weld prone to edge defects on the steel pipe surface during the gas metal arc welding (GMAW) process with argon-rich mixed shielding gas.

(2) After the fillet welds at both ends are completed, a large sealed cavity forms between the flange and the steel pipe. During galvanizing, this cavity may expand due to gas accumulation and, in severe cases, may burst in the zinc pot, posing quality and safety hazards.

(3) The fillet welds connected to the steel pipe have high quality requirements, and ultrasonic testing of the circumferential fillet welds is very challenging. The detection rate of internal defects via ultrasound at this position is relatively low, and radiographic testing methods cannot be applied, meaning the internal quality of the fillet welds at the pipe mouth cannot be assured.

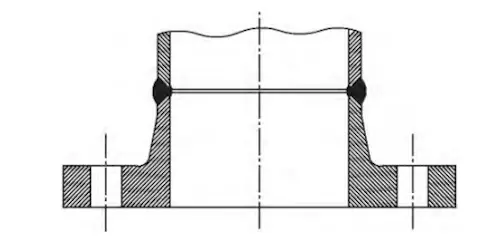

The connection method of the high-neck butt-weld flange and the steel pipe circumferential butt joint is an innovative improvement in structural assembly, welding, and related aspects, as shown in Figure 2. This connection form has the following advantages over the former:

(1) The butt welding seam is the ideal joint form among all welded joints. It provides an equal-strength connection, and its stress concentration factor is significantly lower than that of flat flange and high-neck flat-weld flange.

(2) The circumferential butt welding seam can be further automated and mechanized. After automation, production efficiency can increase by more than 100%, a level unmatched by flat flange and high-neck flat-weld flange. This is one of the most effective ways to accelerate the production capacity of ultra-high voltage steel pipe towers.

(3) The welding quality will be improved in both appearance and internal structure. The detection rate of ultrasonic testing (UT) for butt welding seams is significantly higher than that for fillet welding seams and lap welding seams. If necessary, radiographic testing (RT) can also be used to identify and confirm the size and nature of defects.

(4) The amount of filler metal required for this joint form is the same as that for the high-neck flat-weld flange. Compared with the plug-in form of the flat flange and steel pipe, it reduces both welding material consumption and welding workload, significantly lowering labor costs.

(5) The circumferential butt welding seam has a clear advantage in reducing residual welding stress because the welding seam remains in a free-shrinkage state during the welding process. This allows stress release to occur more easily, and welding seam shrinkage can be mitigated by leaving a gap.

Figure 2 Connection between high-neck butt-weld flanges and steel pipes

Based on the welding characteristics of the two flange types mentioned above, the UHV high-neck flange primarily uses the connection form of a high-neck butt-weld flange and a steel pipe circumferential butt joint.

Related News

- Installation of Main Bolts for Lap Joint Flange in High-Temperature Gas-Cooled Reactors

- Structural Design and Finite Element Analysis of Anchor Flanges

- Key Welding Technology for High-Neck Flange and Steel Pipe Joints

- The Design and Calculation of Stamped Lap Joint Flanges

- Development of Manufacturing Large Anchor Flanges

- Hardfacing the Inner Surface of Long-Neck Flanges Using CO₂ Gas-Shielded Welding

- UHV High-Neck Flange Welding

- Application of High-Neck Flange to UHV Steel Pipe Tower

- Analysis of the Cracking Cause of High-Neck Flanges

- Anchor Flanges for the East-West Gas Transmission Project